US label printer Wegmann Companies has outlined the gains it has made since installing a Domino-powered CEI BossJet hybrid platform in late 2019.

Operating out of St. Louis, Missouri, Wegmann manufactures custom printed labels using extensive hybrid and digital production capabilities. It serves most of the US Midwest, with its reach extending to both coasts, with a focus on markets such as food and beverage, medical, electronics, and others where variable imaging, variable information, and other kinds of variable data is required, if not critical.

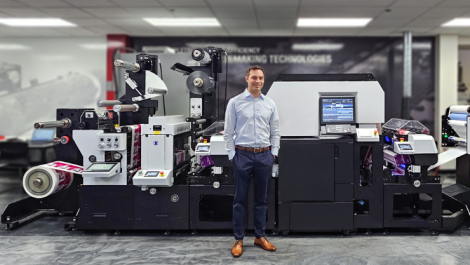

The CEI BossJet as installed is configured with a 40in unwinder, web cleaner, corona treater, foil unit, two flexo stations, turn bar, seven-colour Domino inkjet engine, and two further flexo stations, which are followed by a booklet label making option, semi-rotary die-cutting, rotary converting, matrix removal, and rewinder/sheeter.

This has greatly increased production efficiency at Wegmann Companies as Alex Wegmann, the company’s operations manager, explained. ‘There’s been multiple times where I’ve had 27 hours’ worth of production that would have been traditionally done on a flexo press; now I do it in one shift. From a production standpoint, come hell or high water, our customers need their products delivered on time, so we don’t have time for downtime. I can receive artwork from a customer at 8am, have it on press within one hour, and have labels printed and delivered to them by the end of the day. It’s impressive.’

Mark Wegmann, owner of Wegmann Companies, added, ‘The level of satisfaction on the Domino digital press is very, very high. It’s extremely productive. And it’s also allowing us to go out and find new customers because we have press time to do it.’

He continued, ‘To start the process of choosing a digital partner, we sent out materials. We had them printed, we had them sent back. We eliminated a variety of manufacturers right out of the gate, based on the quality. And then from there we went in and we produced products that were variable image, variable data, just so we could see the quality through the process. Domino shined all the way through it, while each of the others seemed to drop off as we went. And so that ultimately led to the purchase of the Domino unit.

‘For our customers and our prospects, the most important thing to understand is the label world is changing rapidly. And being with a partner that can keep you ahead of the game and differentiate your product on the shelf, or help you track and trace a product, is very important. So that gives us an edge in the marketplace, not only for today, but for well into the future.’

Read more about hybrid printing in the January/February 2021 issue of Digital Labels & Packaging