Hans Kolb Wellpappe has installed a Koenig & Bauer Durst CorruJET 170, as the German corrugated board manufacturer seeks to intensify its focus on digital.

The Kolb Group develops and produces a range of packaging, packaging materials and special corrugated board products.

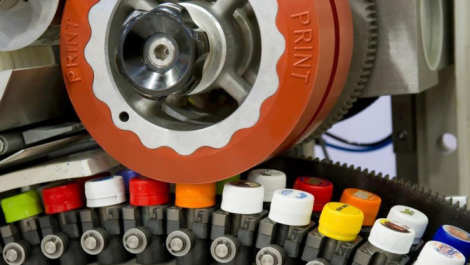

The CorruJET 170 press for the corrugated board industry was developed by Koenig & Bauer, and is based on the company’s extensive experience already gained with its RotaJET platform. It is now marketed through the joint venture between Koenig & Bauer and inkjet printing specialist Durst. Alongside claimed high quality and throughput, CorruJET 170 incorporates a coating unit for gloss or matte coating of four-color images printed using water-based inks. These inks are noted as food-safe and formulations accepted in the Swiss Ordinance, EuPIA, Nestle Ink list, as well produced according to GMP.

The machine installed by Kolb Digital Solutions, at a site close to the group’s headquarters in Memmingen, Bavaria, delivers digital print at production speeds of up to 5000 boards per hour, can handle formats up to 1700 x 1300mm (66.9 x 51.2in), and achieve a print resolution of 1200 x 600dpi

Using the CorruJET 170 for digital post-press printing on corrugated board is part of an extensive investment programme initiated by Kolb over recent years, and is the centrepiece of the group’s digital strategy.

Sebastian Fromm, production manager at Kolb Digital Solutions, said, ‘There is no media in the Kolb Group that the CorruJET 170 doesn’t print. It doesn’t matter whether the substrate is coated, uncoated or even brown liner; incredible flexibility and print quality, no need for post-coating on uncoated boards.

‘This is a very innovative, highly automated solution also for high-volume production with non-stop feeding and non-stop stacking. The CorruJET 170 is the benchmark for quality printing for uncoated markets, especially with the brown and white recycled substrates, which was not possible before, even with conventional technologies.’

Mr Fromm continued, ‘The variety of products we can print is incredible. Take our regular business as one example. A decade ago, there would be one product, now you have the same product in four different varieties, each requiring special packaging that can only be produced digitally viably. Run lengths may be going down, but the varieties will continue to expand. This leads to stronger product diversification and, for us, the opportunities seem to be endless. Some on-demand jobs involve printing as little as 500 sheets, which takes just six minutes to complete, but the press is also used for orders of more than 20,000 sheets. There are almost no set-up costs, whatever the run length, and each sheet costs the same to print.’

Kolb Group managing director Dr Bernhard Ruffing added, ‘The CorruJET 170 is a crucial part of the extensive investments we have made over recent years as part of our great efforts to optimise the technological process chain. Market changes mean that our customers demand fast turnarounds and increased versioning – all produced at the highest quality. Against this background, the focus is increasingly turning to the option of digital post-printing, especially with uncoated markets and brown paper substrate opportunities.’

Koenig & Bauer Durst managing director Robert Stabler noted, ‘With the CorruJET 170, Kolb is extremely well equipped to respond to future customer demands as it continues to open up new market opportunities. The need for fast, automated, reliable and agile printing systems has never been greater in a fast-paced world where the only constant thing is change. Fast shifts in demand require an all-in-one digital solution to meet brands requirements, which we deliver in a partnership approach.’