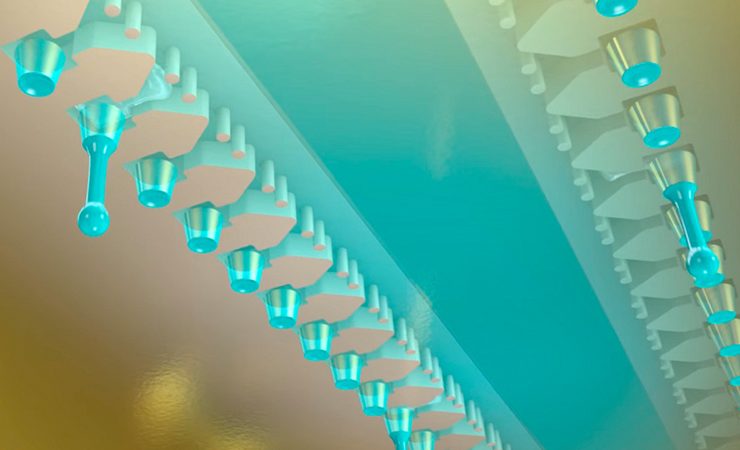

HP is rolling out a new printhead design for its PageWide C500, extending the digital corrugated press’ performance with ink savings per board to deliver improved economics as well as enhanced print quality.

Launched in 2018, the HP PageWide C500 uses thermal inkjet technology, designed for high print quality in demanding production environments, printing at 246 linear ft/min (75m/min) in 1200npi resolution using one million nozzles. Corrugated grip technology delivers precise handling of industry- grade boards for smooth production, while virtual belt technology delivers accurate media motion. In addition, HP’s water-based inks are odourless and free of UV-reactive chemistries, enabling a wide range of packaging applications, including primary and secondary packaging for sensitive uses such as food and personal care while requiring no additional barriers. The inks can comply with even the most stringent global food safety regulations, including Nestlé guidance and Swiss Ordinance.

The new colour printheads enable higher performance thanks to an improved nozzle architecture delivering image quality for HP PageWide C500 converters. In addition, the new design delivers ink savings and extends the lifespan of consumables.

The printheads are now being installed as an upgrade for all HP C500 digital corrugated customers worldwide.

Niv Ishay, worldwide marketing manager, HP PageWide industrial corrugated, said, ‘As we strive for our customers’ success at digital production, we are constantly working to implement improvements to boost press performance. We launched the C500 as a solution to fit mainstream production. Now the rollout of the new printheads will help bring improved economics to digitally printed corrugated packaging.’

Italy’s LIC Packaging is operating the HP PageWide C500 with the new printheads, and director Piero Bertoldo commented, ‘Thanks to the HP PageWide C500 technology, we can convert offset jobs while maintaining high quality, equivalent to what our customers are used to receive from our litho-lamination process. We can consistently keep required brand colours, printing direct to board.’

Richard Brown, president at US converter The BoxMaker, a fellow PageWide C500 user, said, ‘The C500 print quality is always one of our differentiators from our competition. With the new printheads, print is noticeably sharper, and colours are even more vibrant. Our digital corrugated business based on the C500 is growing in volume with the ability to cost-effectively deliver a large number of jobs daily to our customers.’

Read about the latest technologies developed for digitally printed corrugated packaging in the May/June issue of Digital Labels & Packaging, and online here

Read more about the market for digital corrugated printing in the July/August issue of Digital Labels & Packaging; register here to receive the magazine for free