Laser technology specialist Rofin-Sinar UK has successfully rebranded as Luxinar, positioning the company for further growth in the future.

The rebrand from Rofin-Sinar UK to Luxinar took effect from 25 June 2019, and is said to mark a new chapter in the company’s 20-year history, building on the growth the company has seen in recent years.

Luxinar continues to operate from its purpose-built manufacturing facility in Kingston upon Hull, UK, and currently employs over 180 people, both in the UK and overseas, with operations in China, Germany, Italy, South Korea and the US.

Luxinar managing director Klaus Leitner said, ‘While our name has changed, the core of our business remains the same. Our products are some of the most technologically sophisticated in the world, and they exist because of the people at the heart of Luxinar. With that foundation, we are continuing to pioneer cutting-edge laser technology, helping our customers across the world to sharpen their competitive edge.’

The company’s sealed CO2 laser sources can be used on a wide array of materials, from paper and card, to plastic, polymer, foil, textiles, acrylic, rubber, FR4, glass, wood or ceramics. Applications range from cutting, drilling, kiss-cutting and perforating to marking, engraving, scribing and welding. Installed laser sources span a wide range of industries including, but not limited to, industrial, food and beverage, pharmaceutical, personal care and security.

In digital printing and flexible packaging, Luxinar noted that CO2 laser-based machine tools are well-established across many industries and have become the tool of choice for both narrow and wide web applications. Laser processing provides flexibility, with extremely accurate control of cut depth, high repeatability and consistency without the need to change tools.

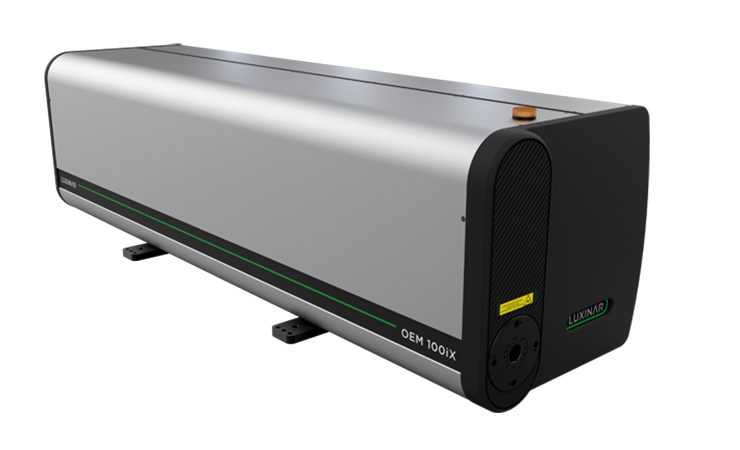

A best seller for Luxinar is its OEM series. It is a versatile system, coming with the same footprint in three wavelengths: 10.6 micron, 10.25 micron and 9.3 micron. The large wavelength option allows companies to design modular machines to process PP, PET, PE, hybrid PET, BOPP, paper and EVOH using the appropriate wavelength. It can be easily integrated into existing production lines, coupled with a galvo-based system, a cutting head or a combination of both.

Luxinar is exhibiting a selection of its technologies at Labelexpo Europe 2019.

Read the September/October edition of Digital Labels & Packaging for a comprehensive preview of digital labels and packaging developments to see at Labelexpo Europe 2019