Esko has developed the Dual Heavy Duty Unit, its latest Kongsberg digital cutting and creasing innovation said to achieve a productivity enhancement of up to 50% in corrugated finishing.

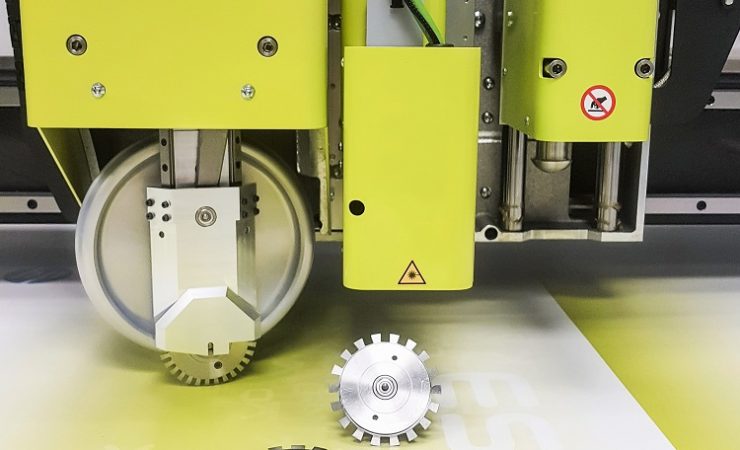

For the first time, Dual Heavy Duty Unit combines two independent wheels in one heavy duty unit. Moreover, Dual Heavy Duty Unit makes it possible for corrugated converters to cut, crease and perforate jobs without the need to manually change tools. Rather, the machine will automatically switch and use the right tool throughout the job, ‘significantly ramping-up production efficiency’, according to Esko.

The engineered design of a Kongsberg table makes it possible to exercise 50kg of downforce on corrugated materials from single to triple wall, without compromising speed or quality. The Dual Heavy Duty Unit delivers better crease quality, it is claimed, even on materials with a high recycled material content.

When combined with the Esko CorruSpeed tool, converters can cut and perforate corrugated substrates with die-cut like quality at full machine speeds of up to 100m/min. The CorruSpeed tool is designed specifically for high-speed digital finishing of corrugated board and is unique in that it uses a static knife in combination with a patented knife foot design to simulate the effects of ejection rubbers in conventional die tooling. This design results in cleaner, more accurate cuts, without burrs. It produces a crisp edge finish even at high speeds, cutting a wide variety of corrugated board types up to 7mm double wall BC flutes.

Russell Weller, product manager at Esko, commented. ‘The new Dual Heavy Duty Unit is perfect for corrugated point-of-sale and packaging jobs, allowing our customers to run without changing tools, delivering productivity boosts of up to 50%. It enables faster machine set-up and higher quality digital cutting and creasing of corrugated board – targeted at sample making and short-run production of corrugated containers, displays and signage – so most importantly speed and quality does not suffer.’

Mr Weller added, ‘Both positions still pack a 50kg downforce and run through material at full machine speeds. When converters add the CorruSpeed tool into the mix, corrugated board can be cut at 100m/min with die-cut like quality that is not achievable anywhere else.’

Dual Heavy Duty Unit and Corruspeed tool can be retrofitted on all existing Kongsberg C, Kongsberg C Edge and Kongsberg XP tables running iPC.