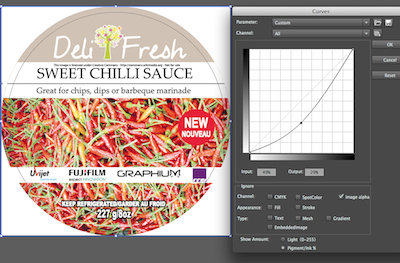

Colour editing using curves – particularly useful for modifications of objects printed on highly reflective metallic/holographic substrates

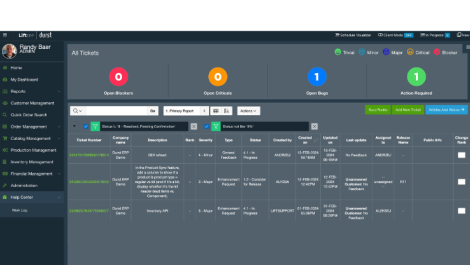

FFEI has launched a range of enhancements to its RealPro Toolkit software, a feature-rich suite of tools designed to overcome the challenges of a label and packaging prepress cycle.

Responding to customer feedback the latest release of RealPro Toolkit includes 12 new features that have been developed to further improve efficiencies in prepress work. These include a new FX module for managing the identification and elimination of banding and other artefacts on flat colours.

Colour editing using curves on both Vector and Raster artwork is also possible.

This is particularly useful for modifications of objects printed on highly reflective metallic/holographic substrates where profiles cannot be effectively made.

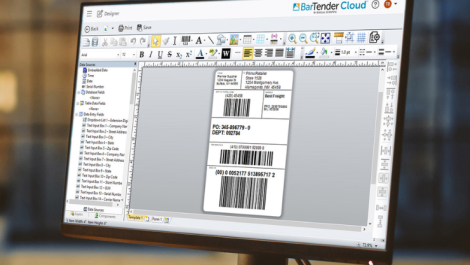

When creating the imposition layout, it’s now possible to select a spot colour from the one-up file to be used for defining the CAD lines. This particular feature was included to improve time saving. If the user knows the spot colour name used in the one-up artwork, they can go straight to creating the stepped job, import the one-up artwork and select the colour used.

Andy Cook, managing director, said, ‘I’ve been overwhelmed with the response from our customers for Realpro Toolkit. It’s always a privilege to hear how our products are helping to transform customers business, especially as it gives my team the enthusiasm to keep pushing the boundaries of innovation. This latest version really is a great set of additional features which I know we are all excited about. It overcomes the challenges that so many prepress technicians face – proprietary file formats, PDF format conversion, lost layers, transparency issues – just to name a few!’

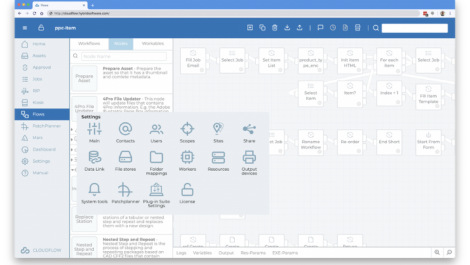

The software consists of over 12 modules designed to address specific pre-press workflow requirements such as file editing and preparation, colour management, trapping and step and repeat tasks. Features also extend to specialist tasks such as cylinder repeats, patterns and artwork pre-distortion.

The suit integrates seamlessly into any existing workflow and is optimised for APPE-based solutions. All linked data remains live inside the final stepped PDF, enabling the 1up file to be easily replaced, and modules such as step and repeat, and trapping, can all be edited from within the workflow. This provides users flexible data that is less prone to errors and quick to process in APPE-based solutions.