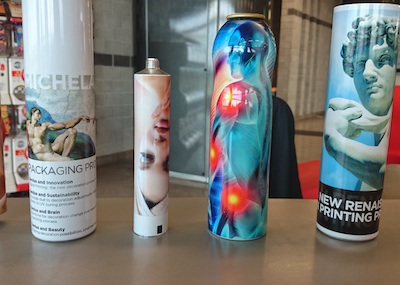

Tubes and cans samples from Italy

Italy is seeing growth in printing direct to pack in the market for tubes. Manufacturer Martinenghi Srl introduced the Michelangelo KX48P inkjet printer for aluminium or plastic tubes and metal aerosol cans in 2014, and there are now several systems installed.

The Michelangelo KX48P can effectively print anything with a hollow body in diameters between 13.5 mm and 66 mm and lengths between 50 mm and 280 mm. It features Konica Minolta heads with UV curing inks, and has an impressive footprint of 7500 x 5500 mm weighing in at 30 tonnes. The solid metal base supports a system of eight linear motor transport modules, coupled to a laser measuring system, for conveying the parts to be printed under the inkjet heads and curing unit, then moving to deliver the print and pick up new stock. Machines can be configured with up to seven colours and throughput depends on the cumulative print length involved that is up to 80 m/min, depending on the resolution chosen.

All batches can be handled as printing a queue, allowing each single tube to be unique. There is a built-in camera detection system and quality is very good, reports technical editor, Sean Smyth, who spoke to printhead supplier Industrial Inkjet in the UK.

La Metallurgica in Albignano, near Milan, is an early adopter. It produces collapsible aluminium tubes for cosmetics, pharmaceutics, food and industrial sectors. The company is promoting its inkjet capabilities as DigIT, offering new possibilities in terms of quality and flexibility, enabling customers to develop new sales strategies and creative projects while differentiating and personalising products.

Good afternoon. Do you print onto aluminium back fill cosmetic tubes? I am trying to find a company to print my hand cream tubes. Tube volume around 45-50ml and I have 5 different scents.

Do you have a minimum order? and what price would 1000 be?

Thankyou

ps my website is under new construction to reflect the expansion of my business and the printed tubes are another step in the expansion.