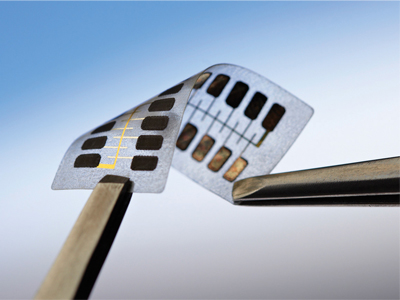

Xerox’s Printed Memory is printed on a thin, flexible substrate and is capable of retaining data for 10 years

At an open day held in its Innovation Centre in Uxbridge, Xerox reviewed the highlights showcased at drupa and explained some of the company’s latest projects, including new packaging innovations.

The 25,000 sqft ‘small city’ that Xerox built at drupa this year had a video camera running from atop its stand. The ‘massive traffic’ it recorded is ‘a reflection of the print industry itself,’ said Kevin O’Donnell, marketing manager, graphic communications at Xerox Europe. The packaging industry is currently experiencing 40% annual growth in digital, with 50% of brand owners printing digital for a faster turnaround.

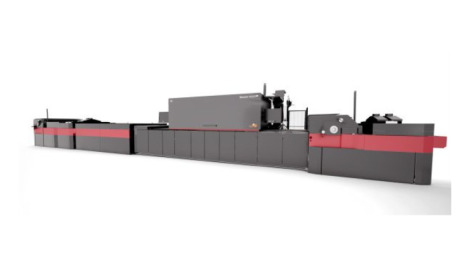

Key to this is automation and integration. The folding and glueing of packaging can take up to an hour to set up; this can be reduced to five minutes with a semi-automatic set-up. Printing labels directly onto objects can also be a quick and efficient process. Showcased at drupa, Xerox’s ‘telephone box’ machine with six inkjet heads covering an area 30 square cm fires ink at a different distance depending on the shape of the item, which moves up and down between the jets. The company showed a video of bespoke metal water bottles being decorated and also highlighted its application for glass objects. Removing stubborn paper labels from jam jars could become a thing of the past.

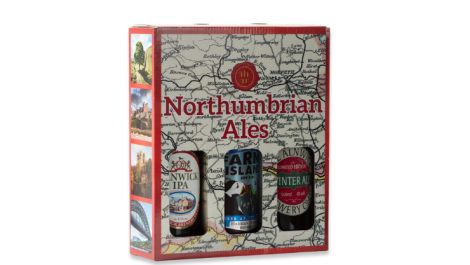

Xerox is also working with Scodix, provider of digital print enhancement presses, to add a layer of polymer gloss or matte effect to toner-based print. This lends itself to ‘really robust packaging’, explained Steve Fordyce, business manager, and is ‘very difficult to replicate from a counterfeiting point of view.’

‘Smarter packaging’ utilising Printed Memory is another application that Xerox is keen to develop. This printed electronic label can collect and store information to determine if a product is genuine and how it has been handled during distribution. Combining printed memory with cryptographic security, which adds a unique, encrypted printed code, creates a secure anti-counterfeit method that is particularly useful for pharmaceutical packaging.

As well as talks and seminars, the day also included access to the demonstration models in Xerox’s Innovation Centre.