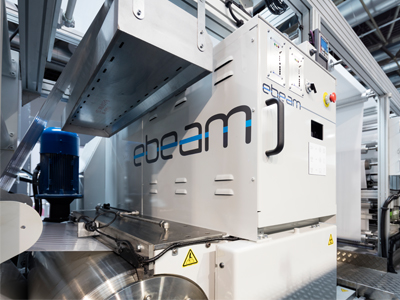

Manufacturer of printing and converting equipment, Edale, has worked with ebeam Technologies to integrate electron beam curing technology into the Digicon 3000.

Co-developed between Edale and AB Graphic International, the Digicon 3000 is a mid-web finishing machine for digitally printed flexible packaging and labels, compatible with the HP Indigo 20000 press. This line is now available with ebeam curing.

ebeam curing is instant and because output from an HP Indigo is often surface print, it is possible to surface coat for protection, and immediately send to slitting and pouch or bag forming. Additionally, ebeam inks and varnish contain no photoinitiators so the risk of migration and contamination of food is negated. Other benefits of ebeam curing include improved print integrity and visual presentation as well as increased package durability and abrasion resistance. It also eliminates the need for solvents, produces virtually no VOCs and is energy efficient.

‘Electron beam curing is a fantastic option for Digicon 3000 customers because it resolves many key challenges they face such as fast turnaround times and environmental factors,’ said James Boughton, managing director at Edale Limited. ‘We are seeing a lot of interest from finishers and converters, especially in the food sector because of the safety aspect,’ he added.

‘We are delighted to be working with Edale on the integration of ebeam curing into the Digicon 3000,’ commented Karl Swanson, VP global sales, ebeam Technologies. ‘The benefits in terms of faster line speeds, food safety and more are clear.’

Currently, three Digicon sales with the ebeam configuration have been made to converters in both the USA and EMEA with two of the customers also including ebeam lamination as part of the configuration.