Supplier of industrial inkjet printhead driving solutions Meteor Inkjet has introduced an upgraded version of its DropWatcher optics. The latest release is designed to deliver higher precision in the visualisation and measurement of ink droplets.

The new update represents a significant improvement to Meteor’s existing dropwatching systems, offering users greater control in analysing and optimising print quality.

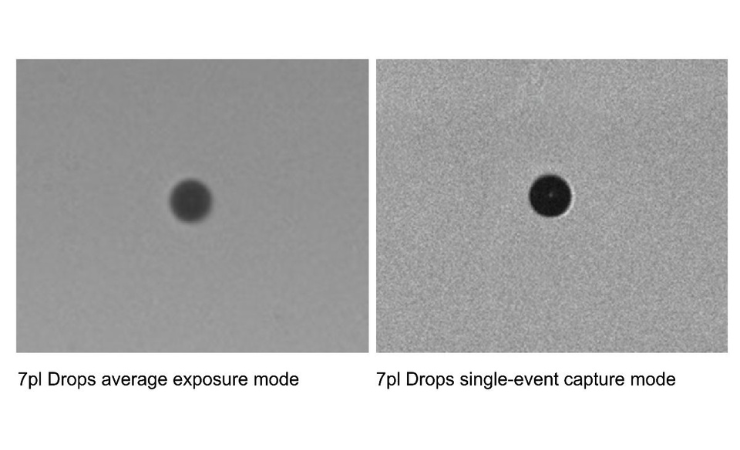

Earlier DropWatcher systems used strobe synchronisation with the printhead firing frequency and long-exposure imaging to capture droplet behaviour. While effective for measuring average drop position and velocity, the technique made it difficult to detect variations such as changes in trajectory, volume, or dynamic effects like ligament breakup and mist formation.

The enhanced DropWatcher optics address these challenges through a high-intensity strobe with addressable pulse outputs and a fixed-objective camera lens that improve image clarity and resolution. The system provides fine control over both strobe and camera exposure timings, allowing users to observe the complete formation of a drop and its contributing physical factors.

Meteor says the new setup can capture single-event frames, revealing variations between nozzles or firing cycles influenced by factors such as print frequency, nozzle duty, and ink formulation. The enhanced sensitivity allows users to visualise femtolitre-scale droplets, helping to identify and reduce misting through waveform optimisation. Lower mist formation can, in turn, minimise nozzle wetting and print artefacts.

The optics can also analyse the first drops ejected after idle periods ranging from microseconds to hours. Detecting issues such as partial drying or incomplete nozzle filling enables the application of corrective pre-pulses, potentially reducing maintenance and cleaning requirements. According to Meteor, this feature can help cut substrate waste and improve overall process sustainability.

“With our new DropWatcher optics, you can see and measure droplet behaviour with a level of precision that simply wasn’t possible before,” said Jonathan Wilson, vice president of sales at Meteor Inkjet. “This breakthrough enables customers to fine-tune their print systems with greater accuracy, leading to improvements in print quality, reliability, and efficiency.”