To succeed in today’s market, many label providers are turning to digital inkjet printing solutions.

‘Digital colour printing technology has become a vital resource for label converters who seek to compete in a market that values customisation and faster response times,’ said Gianluigi Rankin, director of product marketing at Memjet.

Digital printing also helps label providers reduce waste in their label production. In the digital printing process, the make-ready process is significantly curtailed. And, by only producing the number of labels needed, digital printing eliminates the extensive inventories of labels and the waste associated with out-of-date labels.

It is also easier to digitally print labels. Because much of it is automated, label producers can use existing talent or train new users to manage the printing process.

Small solutions, big impact

A new breed of digital labelling and packaging solutions has caught the attention of the industry: namely, mini- and benchtop presses. These presses include features and capabilities of larger, more expensive equipment in a scaled-down solution that is easier to operate and comes at a lower cost.

The mini-press or benchtop label press is an ideal solution for label converters looking for a production-class digital label press with a low acquisition cost to produce short-run, on-demand, and variable data print jobs.

These smaller, more affordable solutions enable brand owners and manufacturers to streamline their processes and take control of insourcing their own label and package production.

Speed and quality in a small package

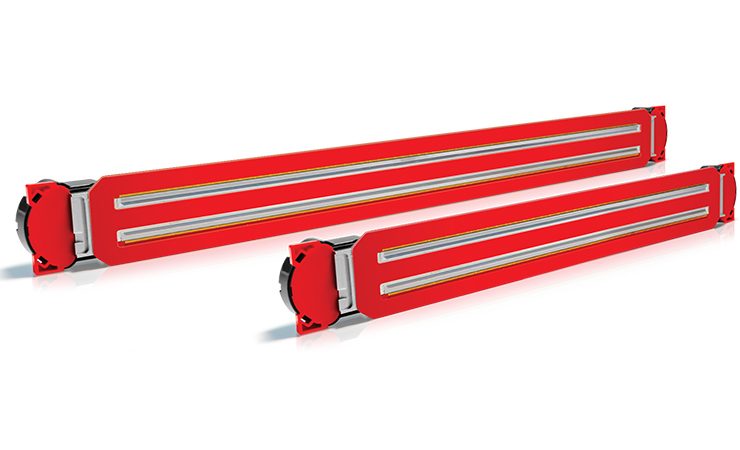

Memjet introduced its new DuraFlex technology at Labelexpo Europe 2019. This new printing technology gives OEMs the resources to create affordable mini-and benchtop entry-level presses with the quality and speed previously unavailable in those types of solutions.

DuraFlex is a modular, single-pass print solution that combines the speed, simplicity, and affordability of Memjet technology with new attributes such as enhanced durability, A4 and A3+ widths in a four-colour printhead, a high-speed data path, and modules that control all printhead functions.

With 1600 x 1600dpi and built-in nozzle redundancy, DuraFlex produces market-leading print quality at print speeds up to 30ips/46m/min. Because DuraFlex is an economical printing technology, it provides OEMs with a low-risk way to move to inkjet or expand their existing product lines by adding new solutions.

The cost benefits of DuraFlex extend to the end user. DuraFlex’s long printhead life minimises intervention rates, resulting in higher productivity and profitability for print providers.

‘DuraFlex was designed to give OEM partners the flexibility and simple product integration needed to keep pace with the trends that are driving the labelling market,’ said Rankin. ‘These OEMs can use DuraFlex to power a range of printers that produce high-quality, customised labels at an affordable total cost of ownership.’

To learn more about Memjet’s DuraFlex technology, click here to watch our video and then download our white paper.

This article is an advertorial; the featured company created the wording and paid for its placement. It has been edited by Whitmar Publications to ensure that it meets our standards.