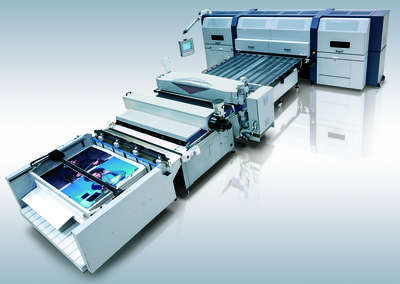

EFI’s VUTEk HS100 Pro features greyscale inkjet

Wide format inkjet printers are mostly used in signage and display applications, for example for free standing displays in retail, but there are increasing numbers of companies using the technology for labels and packaging – and not just in prototyping and printing. By Sean Smyth.

There are many flavours of wide format inkjet printers. There are rollfed, flatbed and hybrid printer models, with a wide range of prices and productivity. There are very high productivity flatbed machines offering throughputs of over 1000 square metres per hour at high quality.

While not a very high productivity solution, a low-cost wide format printer can provide great flexibility to deliver small quantities very quickly. The printer-cutters, mostly from Roland and Mimaki, cost up to a few thousand pounds and there are a great variety of inks, including metallic inks and white, that can produce interesting effects. These work well with most label stocks and are popular in producing low quantities of individual labels, and many commercial printers use them in this way alongside the label converting specialists.

CS Labels in Willenhall, for example, has a pair of Roland DG VersaCamm VS-540 Eco-sol printer cutters, which it uses for some jobs that are not suited for its bank of Xeikon presses. This includes very large labels that do not fit, metallic or fluorescent inks, and some heat sensitive materials that cannot take the fusing temperatures.

Pent up demand

The bulk of the wide format inkjet output is for corrugated and some cartons. In June, the European Federation of Corrugated Board Manufacturers (FEFCO) ran a workshop for its members on developments in high volume digital printing on corrugated which is currently attracting much interest. There are specialist machines, such as the Sun Automation, Engico, Barberan and Bobst developments, but many converters are looking at using their wide format equipment to produce packaging.

According to FEFCO, there is pent up demand for digital printing from the brands and retailers, together with packers and fillers. Offering versioning or personalisation, last-minute changes, providing rapid response to customer demand and accelerated time to market are pushing the move from analogue to digital.

At the FEFCO event, Xanté presented the Excelagraphix 4200, which uses memjet water-based inks. It is a four colour wide format inkjet machine, using five staggered memjet printheads to give a single pass print width of 1060 mm and throughput speed of 545 sqm/hr at full 1600 dpi, twice that at 1600 x 80 dpi. There is an optional portable feed counter, and the machine can handle boards of 1.06 x 2.5 m, up to 16 mm thick. It is aimed at corrugated packaging with pizza boxes highlighted as a particular opportunity.

HP highlighted the Scitex high performance flatbed presses increasingly used to print corrugated packaging. In May at interpack, HP announced it is targeting corrugated with new machines, alongside the larger format Indigo presses for flexible packaging and folding cartons. At the show, it launched the HP Scitex 15000 Corrugated Press for production of corrugated displays and short run packaging.

This develops the model range with high levels of automation for corrugated allowing a top speed of 600 sqm/hr on a bed size of 1.6 x 3.2 m using UV curable inks with 312 HP HDR300 piezo printheads, 52 per colour. The press features the HDR (high dynamic range) function that varies the imaging mode and droplet size according to the image type. There is an integrated automatic media loader that can handle up to four separate board stacks, optimised for use with corrugated sheets without operator intervention. The press has six colours, cyan, magenta, yellow, black, light cyan and light magenta, and HP claims the inks meet ISO12647-7 proofing standards. It operates four print modes, changing the passes that allow users to print from 312 sqm/hr to the maximum of 600 sqm/hr, or up to 120 full-size beds. The front end can be either the Caldera10 GrandRIP+, or Onyx Thrive11.

HP is concentrating on several corrugated solutions, announcing it will provide a simplex version of the T400 high speed inkjet web presses to print top-liner boards. The company is working with leading packaging converters to validate the technology in terms of quality, flexibility and economics. It is conducting trials with its own consumer printer boxes using this technology, at production speeds of up to 182 m/min equating to 12,000 sqm/hr which is much higher than any other packaging solution.

The HP Scitex 15000 press was launched at interpack in May

No hype

Marc Van Damme, FEFCO’s production committee chairman and chief technical officer for VPK Packaging Group, commented, ‘It is not just about switching to digital, it is about rethinking your work process.’ Other companies are entering the inkjet corrugated market. EFI, Durst and Inca Digital all report more users printing short run corrugated and cartons. ‘Digital printing on corrugated board is no hype – it is a solution ready for use in everyday production,’ according to Angelika Christ, FEFCO’s secretary general.

Bill Baxter founded Inca Digital and he said, ‘I have always been an R&D engineer, and I happened to do some work on packaging machinery. When a client asked me how they could print their packs on line, I started looking at what inkjet could do [this was around the year 2000]. Things happened fast after that. Before I knew what was happening, I found myself running a fast-growing company making inkjet printers for retail displays. So I started from packaging machinery, diverted into the retail graphics business, and I now want to go back to packaging.’

At the recent Smithers Pira Digital Packaging conference, Mr Baxter explained the position that packaging offered challenges, and it is really only now that the technology is mature enough to provide reliable high-quality packaging solutions. Inca Digital now has many customers using their equipment to produce short run packaging, for example The Cardboard Box Co and Belmont Packaging. There is considerable blurring between displays and secondary shelf-ready packs, and inkjet is good at producing high quality short runs quickly.

Super wide

Durst first launched the Rhopac flatbed inkjet printer, specifically for packaging, in 2005 and it claims to have been ‘the leader in inkjet technology solutions for the packaging industry for nearly three decades.’ Its 2.5 metre print width Rho 1000 Corrugated is aimed at industrial printing on carton and corrugated board. Parallel stacks can be loaded and printed together, board is transported using specially designed edge-holder grips and sheets are held in position on the print table under strong vacuum through adjustable chambers according to the media size. Alternatively there is a roll infeed with cutter. Mechanical 2-point registration controls the X-Y direction with a pulley system moving board(s) to make sure they align to the edge, allowing accurate printing on multiple sheets together. It uses UV inks and there is an integrated post-print roller coating system with UV varnishes to provide a high-gloss finish. The automated stacker can handle several sheets together, loading directly onto pallets. The top speed is some 500 sqm/hr, over 150 2.5 x1.2 m sheets, and Durst claims the machine provides the same quality as a laminated offset print.

The Durst Rho 1000 press is aimed at industrial printing on carton and corrugated board

EFI is highlighting packaging with new UV and LED inkjet printer sales that it said provide customers digital converting opportunities in corrugated, folding carton and flexible packaging markets. While much of this new activity comes from traditional converters bolstering their litho and flexo operations, commercial printing and signage firms are also making strategic purchases to establish profitable packaging operations. In response to the demand, EFI has continued to develop its portfolio to include more packaging hardware and software, improving the packaging capabilities of its VUTEk inkjet products.

Corrugated and folding carton packaging is growing on the 3.2 metre wide VUTEk HS100 Pro press. This features greyscale inkjet to boost image quality and widen the colour gamut to allow more spot colour matching with optimised print head set up to reduce ink consumption. The innovative pin and cure technology delivers precise UV ink laydown with variable gloss control. The eight colour machine can include white and be integrated to web-to-print and MIS solutions with native JDF connectivity.

In April, EFI bought the Rhapso Group which makes software for corrugated packaging production scheduling, PC-TOPP. According to Frank Mallozzi, senior VP worldwide sales and marketing at EFI, ‘The continued growth and interest EFI is seeing in this market reflects our ongoing commitment to be a valued partner for businesses that want to take advantage of the accelerating opportunities in packaging. We are very proud to work with many of the world’s best packaging converters and, as always, we are committed to helping them grow profits, reduce waste and cut costs using the most innovative digital printing and workflow technologies available.’

Thinking forward

It is not just labels, cartons and corrugated. Thermoplastic inks for rigid plastics and metals are available allowing many new applications to develop. INX is a leading ink supplier for two- and three-piece metal cans and the INXDigital subsidiary is selling wide format inkjet to metal decorators for prototypes and short runs with the MD800 and MD1000 models. The six colour MD 1000 uses Toshiba-Tec heads and UV curable inks that can be successfully varnished, stamped and formed into final products using the standard metal forming equipment.

In the words of Bill Baxter, ‘I’ve heard many views from companies from lots of sectors of packaging. But interestingly, both marketing and operations want what digital print can give them. One thing I’m sure of – when they get hold of the right equipment, the customers will find a hundred ways to use it that nobody ever thought of. That is what we saw among our Inca customers, and it happened wherever digital print replaced analogue.’

These innovations are irrevocably changing packaging as wide format inkjet is being adopted by forward-thinking printers and converters.