A range of labels produced on Primera equipment

There is a size of label printer for everyone on the market today. Low cost smaller label printing systems abound and these will produce high quality vibrant labels in no time at all. Neel Madsen looks at a few.

The beauty of digital label printing is that there is a system for any job no matter the size of the label or the length of the job. Small, fast desktop systems can be brought in house by small brands or businesses that need on-demand short runs for immediate use, or added to a commercial printing company’s offering. If you need a bit more capacity, there are also many medium-sized options available without having to go to full industrial sized presses. The choice is almost endless.

Maxing the capacity

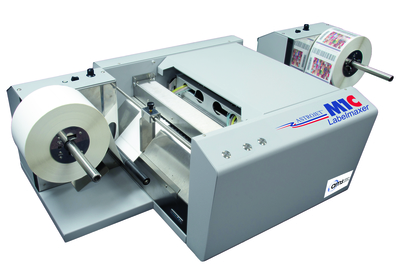

Manufactured in the US by Astro and exclusive to AMS (Addressing & Mailing Solutions) in the UK, the M1C Labelmaxer is a professional desktop printer featuring memjet printhead technology enabling prints speeds at up to 18 m/min at 1600 x 800 dpi in normal mode and 9 m/min at 1600 x 1600 dpi in black and colour high quality mode.

The printer has five high capacity ink tanks (250 ml) for cyan, magenta, yellow and two blacks. It can print on media from 0.13 mm to 0.33 mm in thickness. Print widths run from 50 mm to 222 mm and the printer can produce roll or fan fold labels with plain or pre die-cut stock. Colour profiles can be matched to suit the required substrate.

The Labelmaxer is a convenient fast solution for companies needing high quality labels on demand. It is sold as a standalone system or with finishing units supplied by Labelmate. Kevin McPheat, managing director, said, ‘We spent time looking for the right label printer in terms of price, quality and speed to offer our customers. Companies that print labels in small quantities and bright colours can now promote their brands much more cost-efficiently.’

According to AMS, typical users include label converters wanting to offer high quality very short runs, smaller commercial printers wanting to offer a label service to local businesses as an add on, as well as manufacturing companies needing on-demand label printing in house.

Rapid converting

Released earlier this year by its Australian manufacturer and distributed in Europe by ITE (Impression Technologies Europe), the Rapid XL220 is an inkjet label press with multiple finishing and converting options. Also featuring high speed memjet printhead technology, it produces full colour labels on a variety of inkjet-receptive stocks, in resolution up to 1600 x 1600 dpi using memjet water-based inks. The web width is 220 mm, travelling at up to 18 m/min (at 1600 x 800 dpi).

The unwind and rewind stations are built to Rapid’s high engineering standards and the base model XL220 has inline die-cutting, matrix stripping and lamination. Additional optional modules include flexo coating, cold foil embellishing, embossing, slitting and spot coating. An RFID converting station is currently under development.

A great example of a printer taking advantage of this machine’s short run high quality label printing capabilities is Evolution Labels of Brookvale, in New South Wales, which was recently named as the buyer of the first XL220 in Australia. The announcement was made in May, but the customer name was withheld at the time.

Scott Fredman, Evolution manager, said, ‘We have been developing a new business concept for the label industry here in Australia and wanted to remain below-the-radar during this phase. We are now ready to roll and the XL220 is central to our vision for on-demand short run, full colour labels printed on-time, with minimum fuss and delivered to trade label printers anywhere. Our primarily trade-only model means that conventional label printers can accept orders for short run quality labels that are not economical to put onto a flexo or offset press, without the need to invest in new plant and digitally – skilled labour.’

The M1C Labelmaxer from AMS

Popular combo

The combination of the CX1200e Color Label Printer and FX1200e Digital Finisher is a popular solution from Primera Technology. Many customers choosing this set up are small businesses, such as wineries and bakeries, which use the fast turnaround, short runs and on-demand delivery of labels for their stock. The combo will be on show at the PPMA Show, taking place at NEC, Birmingham, from 30 September to 2 October.

The Primera LX900e is a compact desktop label printer which offers a print resolution of up to 4800 dpi using the latest in high-resolution inkjet technology called Primera Imaging Perfection, which promises razor-sharp text, graphics and photo-realistic printing. Printing labels of widths between 19 mm to 210 mm, the colour droplet size is 4 pl (black is 5.5 pl) and the print speed is up to 4.5 inches in draft mode. It has a semi-permanent printhead, which can be replaced if needed.

The application range can be expanded by adding the company’s ACS-216e auto cutter, which features a heavy-duty rotary cutter which can cut through label stock, heavy papers and plastics up to 216 mm in width.

For top end applications, Primera has the FX400e Foil Imprinter, an optional accessory to the LX series of label printers, which it presented recently at the London Wine Fair. This allows overprinting with gold and silver foil effects, applying borders, fonts and other graphics to inkjet- or laser-printed labels.

Other colours such as red, blue, green and yellow as well as clear film are also available. When added to inkjet-printed labels, the clear film gives a glossy finish and also makes labels resistant to water, chemicals, and cleaning solutions. Additionally, it adds UV resistance to the printed output, allowing longer exposure to natural and artificial light sources.

Affordable price tag

‘Labels and packaging is one of the fastest-growing segments of the printing industry,’ said Peter Barton, director of EMEA business for Reprographic Technology International (RTI). ‘It is technology driven and it is consumer driven. Everything that is sold has to be packaged. Everything ends up in a package, whether a prescription drug or a packet of biscuits. There are more and more small companies doing food items, and that is a real opportunity. There are also so many different applications for labels, from industrial needs to ‘cottage industries’ and so on. The market is almost infinite.’

The company has the Vortex 850R label printer powered by memjet technology, which makes it possible to print in full colour at 30 cm per second (an effective speed up to 10,000 labels per hour at a 4 x 6 inch label size), and up to 215 mm paper width. The system features a roll-to-roll or a roll-to-cut printing option with variable data, making it ideal for economic and efficient printing in the label market.

Each machine has a thermal memjet printhead with five channels (CMYKK), containing 70,400 nozzles, delivering a 1.2 pl droplet. This equates to seven hundred million ink drops per second and an output resolution of 1600 x 1600 or 800 x 1600 dpi.

Erik Norman, president of RTI Digital said: ‘Our Vortex range is all about bringing a wider capability to the modern print provider, with an affordable price tag. The new single-pass memjet technology that we have incorporated into our range, and which has been successfully rolled-out over the past two years or so, is enabling our customers to gain business that they would not have been able to take before. It is not so much a question of replacing old methods, as augmenting those methods, and providing those customers with new business opportunities.’

A finishing solution

Intec Printing Solutions offers the Edge 850 label printer. It has recently introduced a digital label finishing solution, the LCF215, which runs at 3 m/min and uses contour cutting of printed label rolls into any shape. The finisher can also add lamination for additional surface protection and light fastness.

Hertfordshire-based company Last Bros Ltd has recently invested in the LCF215 finishing machine. Established in 1948 by Ken and Alan Last, the printing company specialises in the production of self-adhesive labels, tabbed dividers and large format print. With some big national contracts, including BUPA healthcare, city councils and police forces, it is a great example of a thriving UK print business.

Last Bros currently use UV letterpresses combined with a flexo press for printing and finishing UV labels, and an inkjet system for short run colour labels. However, the company found that setting up its flexo press could often prove to be a time consuming process and there was a requirement for a more efficient label finishing solution.

The company therefore visited Ipex this year with a view to investing in a high quality digital label finishing system that could streamline the production workflow. Having been impressed by the demo of the LCF215 on the Intec stand, the decision was made to invest in this machine.

Features of the finishing machine that really grabbed the attention of Last Bros were the easy set up of the machine, the registration which has up to 3 register marks and the ability to die-cut, laminate, slit and remove the matrix in one pass. The LCF has been up and running for some time now and is proving to be a valuable addition to the company’s production environment.