Irongate Digital printed chocolate boxes for Cadbury

A number of new digital presses for cartons have been introduced over the past few years. Technical editor, Sean Smyth, looks at the current state of the market and where it is going.

The first of the HP Indigo 30000 presses (B2 format for cartons) are now installed and producing in Europe, the USA and Israel. In Germany, Leupold is selling cartons from its Canon Océ InfiniStream press. Xeikon has streamlined its integrated carton manufacturing system to include coating and die-cutting. The B2 inkjet machines from Screen and Fujifilm are making new types of cartons, while the Konica Minolta KM-1 is being readied for launch. And there are noises that the Landa machine is close.

Growing business

Many printers have been using digital presses to print short runs and one-off promotional cartons for sweets and chocolates for years. This is an interesting application for many commercial printers, often using cutting tables to finish the carton, which is then hand-folded and glued. Some have grown the business. In Derby, Irongate Managed Communications has been a leading supplier of corporate gifting and photo gifts, and in September, installed a Xerox iGen150 at its digital print facility with short run cartons and packaging a key product sector.

However, this very fragmented production space is developing. HP Indigo and Xeikon have developed their specialised webfed equipment to provide specific carton production systems. These have proved to be very popular with customers printing significant volumes, across the world. While these toner machines are steadily being improved, the real action is in a range of new machines that are designed for carton production and will handle larger formats and thicker board, with the necessary board handling, workflow and finishing considerations built in, rather than being an afterthought.

Xeikon’s folding carton suite adds to the optimised 3000 series presses including the 3500 with a print width of 508 mm. The company has introduced new toners and fusers, the Alpine, which has a flexible outer layer to help smooth print on uneven and textured media such as recycled board. The fifth unit will have either orange ‒ to broaden the colour gamut ‒ or a durable clear toner that can be hardened under UV radiation. There are several finishing options that can be integrated into a single pass system, using either a Kama flatbed die-cutter or a Bograma sheetfed rotary die-cutter with RotoMetrics cutting dies. Xeikon said the system can deliver five colour print at speeds up to 19.2 m/min, with a single operator controlling the line.

The HP Indigo 30000 carton press is now available and there is a steadily growing user base. This is a B2 format simplex sheetfed machine, optimised for carton production handling 600 micron board with a priming unit. HP has partnered with several finishing companies, including a Tresu iCoat 30000 coater, for UV or water-based varnish. Kama is providing die-cutting and folder-gluing equipment. One of the first adopters is Israeli converter Heret Printing based in Yavne, who specialises in high end cosmetics using high end substrates, including metallised and specialty stocks. It bought the machine to reduce turnaround time while maintaining print quality and colour fidelity. Avi Noiman, CEO of Heret Printing, commented that, ‘In the cosmetics market, many jobs are done in small batches, and it can take a lot of time and calibration to get good results from printing on offset equipment. In addition to reducing the amount of time it takes to get to full production, the HP Indigo 30000 opens up possibilities for us to expand our offerings and develop new markets.’

Big beast

Canon Océ has the impressive webfed InfiniStream press now producing cartons for customers at the first user, Schneller Leupold based in Schwabach, in Germany. The concept machine was installed in January but is now very different, with seven colours and an inline (analogue) coater from Tresu. The quality is much improved, with good end density and the seven colour mode with orange, green and violet that increase the gamut, very useful in matching more spot colours. The print is recyclable, with tests showing samples are Ingede test 11 compliant.

It is a large beast of a machine. The press in the Poing demo centre is some 30 metres in length, with another five for the Bielomatik sheeter (with no coater). Océ has refined the electrophoresis process that uses chemically produced low viscosity liquid toners. It features an elegant 2 micron thick layer that transfers under electrostatic control, rather than heat and pressure. There is a seamless blanket that transfers toner to the substrate, using technology similar to that used in toner belts for the mono webfed toner machines it makes. Work is focused on improving usability, to minimise operator intervention that is currently required so only a single operator will be needed. The range of boards that are approved is growing and there will be automatic splicing to increase the uptime.

The launch has been slower than originally planned, but Océ is still very confident. Pricing has not been released, but the company intimates the press will be in the region of £2 million, and be cost competitive on jobs up to the equivalent of 3000 B1 sheets. They are currently finalising the next lead customers, with commercial availability in 2016.

The B2 inkjet presses are also being aimed at the sector with the Fujifilm JetPress 720 and Screen’s Truepress JetSX producing cartons at their first installations.

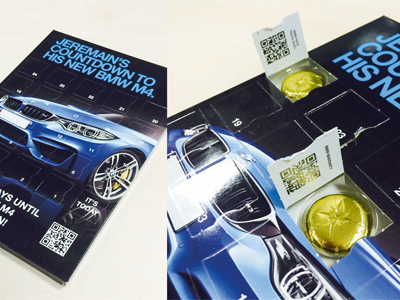

BMW personalisation countdown carton from Snap

It’s a carton, Jim

Snap plc through its SnapaJack.com site is offering a whole new range of personalised and gift cartons including wine and chocolate. Snap is a trading identity of RCS in Retford, Nottinghamshire, who has the Screen Truepress JetSX that was installed in 2012 that is used to produce a range of novel items and cartons. MD Michael Todd is developing a new type of carton product, the countdown calendar box and is interesting holiday companies and car dealers who are identifying up-selling opportunities. He said, ‘Our calendars are available in seven up to 35 days to go, they arrive the correct number of day ahead of the event, uniquely personalised to that client and their experience. Each window offers a chance to promote benefits of the purchase and reinforce the decision in the clients mind or offer an up-sell at a time when the client is at his most ‘suggestible’.’

Wim Konig, business development manager for Screen Europe, said, ‘I think that Screen has a great story to tell, personalised folding cartons with the ability to print on pre-cut and pre-creased 600 micron packaging boards. In fact the only way to print very short run length folding cartons economically.’

I don’t think Screen is the only solution available now but it is certainly part of the changing landscape of carton manufacture with new applications coming on stream as converters re-examine their business models.

More coming

Konica Minolta hopes to have the KM-1 UV inkjet press in operation early in 2015. This has been developed with Komori which will also sell the machine as the Impremia S29. Komori is providing the sheet handling and transport, with Konica Minolta supplying the inkjet heads, inks and LED curing system. The machine will be capable of running single-sided stocks up to 600 microns at speeds up to 3300 sheets per hour with maximum sheet size of 585 x 750 mm. No pre-coating is needed and Konica Minolta is working to print to ISO12647-2 standard.

Landa reports it is progressing well with the S10 single sided sheetfed press, which will be the first to market with cartons a key application. Gilad Tzori, vice president, product strategy at Landa said that there are currently three Beta presses in different stages of manufacture at the Rehovot site in Israel.

These are producing full size high quality sheets which have a colour gamut some 15-20% higher than competing technology, including offset. They are happy with the progress and expect to ship the first machines to customer sites next summer, maybe earlier if they agree with an Israeli customer, then into Europe and the USA. Full commercial availability will be in early 2016. The EFI frontend ‘A Fiery on Steroids’ is now working well and the press will be equipped with a full scanning inspection system from AVT (Advanced Vision Technology) to guarantee quality and consistency.

So we will see a new range of digital carton presses coming to market over the next few years. These will remove many of the limitations of current digital machines in terms of limited format and board thickness, meaning many cartons are technically impossible and will not fit on existing finishing equipment. Those presses have low productivity, making even short runs too expensive. This will change and as the pioneers report their experiences many others will follow.