Suppliers are increasingly addressing the gap in the market between entry-level label printers and the big industrial production presses. One offering comes from Konica Minolta, which held an event in April to show its label press in action at UK customer Soabar. Neel Madsen was there.

Run lengths are getting shorter – much shorter – and customers want their labels printed ‘yesterday’; some of them even want each label to be different. What should a smaller label printing company do to meet these demands without breaking the bank and changing its whole structure? Soabar Ltd, in Leicester, found that the bizhub Press C71cf label printing system from Konica Minolta solved this dilemma.

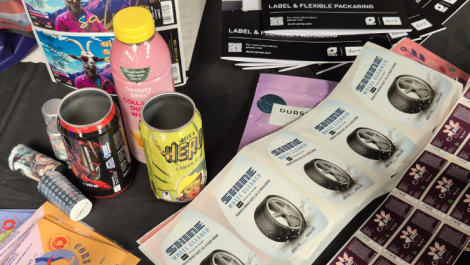

The press was complemented by the investment in a new finishing line from AB Graphic, bought to keep up with the new digital capacity. Soabar chose a Digicon Lite 3 offering semi-rotary die-cutting with a max repeat of 520mm, auto-slitter knife set-up and dual rewind, while a flexo print station can add cold foiling, gloss or matt varnishing, and lamination to the labels for added value.

Road to success

Before the visit to Soabar, Konica Minolta (KM) and BPIF Labels had arranged a workshop at a nearby hotel to look closer at profitable digital label production. Presentations from Herma, Label Traxx and AB Graphic International covered multi-layer adhesive technology, management information systems and finishing, while KM itself gave more detailed information about the C71cf press and answered questions from the delegates.

First up John Hill, UK technical/QA manager at Herma, spoke about developments in adhesives and claiming that the future is “multi-layered”. The company has recently invested heavily in developing a new multi-layer cascade coating technology. This means that several layers can now be engineered into the adhesive, each with its own separate function, such as reducing migration risks, security features and higher tackiness for difficult applications. He explained that this innovation offers significant product enhancements and is opening up new markets for the company. Advantages also include higher press and application speeds, less downtime and improved tooling life. The technology is now used across the board for all Herma adhesives.

Katy Nightingale, business solutions at Label Traxx, explained why it is important to have the right, fully functioning MIS in place when venturing into digital printing. She looked at all the steps involved, saying, ‘A quote often only covers a small part of the whole process and doesn’t include the time spent on admin and other tasks, but with digital, placing an order can take a lot longer than the actual printing of the job.’

If an MIS is not working satisfactorily, staff will lose trust in the system and may start using their own workaround methods. All this extra activity can quickly erode productivity and reduce profit. She said, ‘Margins are small so every part of the job is important and needs controlling. Using your MIS to manage and measure in order to become a successful label printing business is essential.’

A new Digicon Lite 3 converts the labels from the KM press

‘When making the transition into digital, it is vital that you have both pre-press and finishing in place. Otherwise, it becomes impossible to make your business model work,’ said Matt Burton, who is business development manager at AB Graphic International. He particularly stressed minimising set up times, automating processes and maintaining a high throughput rate as key to successful finishing. ‘Soabar chose automated options on their Digicon Lite 3 machine, which in fact means they have capacity to cope with two KM digital label presses,’ he stated.

The future for finishing equipment, explained Mr Burton, is more automation achieved through JDF/JMF connection with the MIS and workflow systems, taking the onus away from the operator. For the future, ABG is looking at digital embellishment and also continues to invest in laser cutting technology.

Finally, BPIF Labels took the opportunity to introduce its new chairman, Graham Backhouse, who said, ‘John Bambery is a hard act to follow. He has done a great job over the years and I will try to continue his mission and build on all his hard work.’

Into digital

Konica Minolta premiered its label printing system, the bizhub Press C71cf, at Labelexpo 2015, after first presenting a prototype in 2013 on the Miyakoshi stand.

The toner-based press is an affordable option for printers entering into digital label printing, if their operation does not warrant a big machine, but they still want to offer high quality, full colour digital labels to customers. KM developed the roll-to-roll, four colour press specifically for short to mid run on-demand printing at a competitive price. This came after the company had surveyed the market and talked to printers about their needs and the ideas they had for future development of their companies.

The compact footprint of the press – it takes up less than 3.5 x 1m including unwind and rewind units – also appeals to smaller operations as does the ability to use existing substrates. The simple click-charge cost model incorporates toner, service and consumable parts, regardless of coverage, making it easy to see the real job costs. All in all a great option to get into digital without major upheaval.

This is still a new market for KM and the company is working closely with Soabar to learn more about how they market themselves, explained Bernard Cassidy, senior marketing manager. He said, ‘Konica Minolta is putting a lot of energy globally into the industrial print sector. What happened in commercial print segment years ago is now happening in the label industry. Volumes are shifting from conventional to digital.’

Exciting new step

As the first user in England and the second in the UK, Soabar installed the C71cf in January this year at its home in Whetstone, southwest of Leicester. The company is an established label printer with a suite of flexo presses and finishing equipment. It also sells and supports a range of small thermal printing systems for in-house industrial use.

The decision to invest was made after outsourcing its digital label printing needs for around three years, and it is a business model that makes sense to Mr Achurch. He said ‘We have been building up a nice amount of work in digital labels in the past few years and purchasing our first digital press is an exciting new step for us. The KM system is based on a click-charge that includes toner, parts and labour, so we don’t have to worry about any of that when we do an estimate.’

Around 10% of the labels printed at Soabar are now produced on the digital press. The average digital print job is around 300 metres and the longest so far 1200 metres. Currently the press is running two to three hours per day as the company finds its feet, but with plans to install a management information system, the operation is set to expand.

It is clear that for Soabar the KM solution has been the perfect match; one that can take them safely into the future. ‘This equipment is more than comparable to some of the other bigger machines out there. It is good value for the money and the whole package was perfect for us. Together with the support we have had from Konica Minolta, the transition into digital has been very easy,’ said Mr Achurch, who was also very pleased with the open house event. He said, ‘The day has gone really well. This is a new venture for us as we normally operate a bit under the radar.’

Read the full July issue here