Digital print technology offers several advantages in flexible packaging production despite the traditional dominance of wide web conventional printing presses in this high-volume market. By Michal Lodej.

When it comes to flexible packaging and digital printing presses, the question is not whether digital can do it but rather is digital cost effective. There are example of brands moving over to digital for packaging where variations in design are required or for low order quantity but is this the limit to digital presence in the flexible packaging market.

Mark Stephenson, business development manager – Packaging and Inkjet Business, Fujifilm Graphic Communications EMEA, said, “There is indeed a growing narrative suggesting that digital printing is now a ‘mature’ solution for flexible packaging. At Fujifilm, however, we think that’s a generous label. While digital has certainly made inroads, particularly in the label market, the flexible packaging sector has historically lacked true production-ready solutions that meet the industrial scale and stringent requirements of the market – at least until very recently.

“For decades, manufacturers have promised digital solutions for flexible packaging, yet most offerings fell short, whether due to limited productivity, lack of food-safe ink options, or over-reliance on hybrid technologies that compromise the benefits of going fully digital. Many existing presses were either label machines adapted for flexible packaging or short-run solutions never intended to scale.

Fujifilm’s Jet Press FP790

“Other solutions have relied on UV inks, which aren’t suitable for food-safe applications. And while there have been announcements and prototypes over the years claiming to revolutionise the space, few have translated into fully commercialised products ready for mainstream production. In short, digital has been in the conversation – but rarely in the factory.”

Mr Stephenson continued, “At Fujifilm, we’ve taken a fundamentally different approach, we purpose-built the Jet Press FP790 specifically for flexible packaging. Our focus has been clear: to meet the real world demands of 24/7 industrial production, while maintaining the environmental and application standards that converters and brand owners expect.

“We’ve also made sure our pricing model feels familiar to packaging converters. Instead of charging per click, like many digital systems, we use a “pay-per-box” approach that’s more in line with how materials are bought in conventional analogue printing.

“Unlike many solutions that rely on UV inks, unsuitable for food applications, or hybrid systems that use flexo units for white, we developed a water-based inkjet system including a high-opacity digital white. The Jet Press FP790 has dual white printhead arrays, giving excellent density in a single pass, all while staying compliant for food packaging.

“In terms of scale, the Jet Press FP790 isn’t built for special projects or occasional use. It’s a high-productivity platform, engineered for mainstream manufacturing. Our business model also aligns with analogue expectations.

“We’re not claiming digital will fully replace analogue any time soon – nor should it. But we are enabling customers to scale both technologies in tandem, choosing the best-fit solution for each job. With the Jet Press FP790, our customers, like Eco Flexibles in the UK, are already transforming their business models, offering faster turnarounds, lower waste, and greater agility without sacrificing production volume.

“Ultimately, to answer the question: today’s presses are enabling printers to achieve greater scale with digital technology by finally closing the gap between concept and execution. But to call the market ‘mature’ is premature. Instead, we’d say digital for flexible packaging is entering its first truly production-ready era, and Fujifilm is proud to be leading that evolution.”

Hybrid options

For some, digital/flexo hybrids make a better case than pure digital in flexible packaging. They combine the flexibility and cost-effectiveness of flexo printing with the versatility and variable data capabilities of digital printing. The hybrid approach can result in enhanced print quality, improved substrate compatibility, and greater overall efficiency.

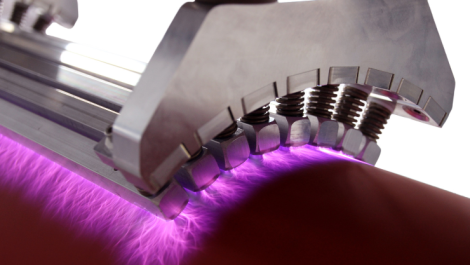

Tom Cavalco, executive vice president, Mark Andy, explained, “One of the disadvantages of digital presses in this sector has always been speed – now with the Mark Andy Digital Series HD HighSpeed 1200, capable of 140m/ min, this issue has been addressed. Another issue with hybrid presses and flexible packaging substrates is ensuring compatibility and maintaining consistent print quality across different materials. This requires careful calibration and sometimes additional investment in equipment to handle the complexities of various substrates. Having in mind that substrates vary from order to order. Good corona surface treatment is important to ensure consistent performance.”

Mark Andy adapts its hybrid technology specifically for flexible packaging production by integrating features that optimise the printing process for flexible substrates, ensuring reliable performance and high-quality output. Web conditioning with controlled corona treatment technology is one example.

Mr Cavalco concluded, “Looking ahead, Mark Andy continues to innovate with hybrid presses in the flexible packaging sector. Future plans include advancement in automation, digital integration, and sustainability features aimed at further enhancing productivity and reducing environmental impact in packaging production.”

Getting personal

The flexible packaging industry, a constantly evolving and crucially important sector for the preservation, protection, and presentation of a vast array of products, is today under a major transformation. This metamorphosis is being driven by the progressive adoption of digital printing technologies. Traditionally dominated by analogue printing methods such as flexography and rotogravure, the flexible packaging industry is witnessing a paradigm shift, with digital printing emerging as a powerful engine of innovation and change.

Marco Murreli, business development inkjet for labels and flexible packaging sector, Durst, said, “One of the main drivers of this shift is the growing demand for personalisation and differentiation from brands. In a saturated and competitive market, companies are constantly seeking ways to distinguish their products and create a closer connection with consumers. Digital printing perfectly meets this need, enabling the creation of unique packaging with variable graphics, targeted promotional messages, and even the possibility of personalising each individual piece. This capability opens new frontiers for marketing, allowing for more interactive and engaging campaigns, such as limited editions, seasonal packaging, or promotions linked to specific events.”

Beyond personalisation, digital printing offers significant advantages in terms of efficiency and sustainability. The reduction of material and ink waste, the elimination of printing plates, and the ability to produce only the necessary quantity of packaging contribute to a leaner production and a lower environmental impact. Furthermore, the rapid and low cost prototyping capability offered by digital printing accelerates the development process of new packaging, allowing companies to respond more quickly to market trends and consumer needs.

Mr Murreli continued, “Durst presses are able to print on substrates for shrink sleeves, pouches, tubes and many more. This without giving up the ability to print regular self-adhesive labels, giving the opportunity even to small label converters to differentiate and enter other added value markets. Proprietary ink formulation and special hardware developments enable our customers to have success in the shrink sleeves market, IML and tubes where commercial applications are in the market since months.

“However, the widespread adoption of digital printing in flexible packaging is not without its challenges. The initial investment costs in digital equipment can be high, and the production speed of digital machines, although constantly improving, may still not match that of analogue systems for very high print runs. Moreover, it is necessary to further develop inks and substrates to ensure optimal performance in terms of resistance, barrier properties, and suitability for food contact. Despite these challenges, the transformative potential of digital printing for flexible packaging is happening.”

Since digital printing arrived on the scene it has been a true catalyst for a change in the labels and packaging industry. Its ability to offer personalisation, efficiency, sustainability, and fast turnaround times is opening new opportunities for brands and responding to the needs of a constantly evolving market. As digital technologies continue to advance and become more accessible, it is likely that we will see an increasingly profound transformation in the way flexible packaging is designed, produced, and used, with significant benefits for the industry, consumers, and the environment.