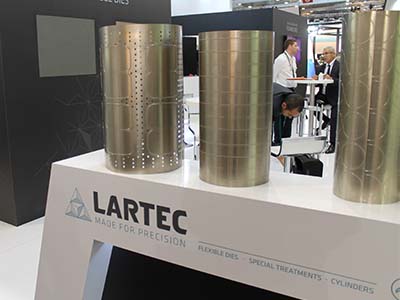

Flexible dies from Lartec shown at Labelexpo 2017

Die-cutting is an essential component of any kind of label printing solution. Nessan Cleary examines some of the wide range of tooling and machinery options on the market.

Just about every label that is printed will need to be cut out in some form, regardless of any other finishing steps that might be required. This might involve through cutting or kiss cutting, or for creating perforations or creasing, but regardless of the cut, the tried and trusted method has been rotary die-cutting. However, digital printing is generally associated with short runs, so we need the precision cutting associated with die-cutting, but in a less expensive solution suitable for shorter run lengths.

Flexible dies can handle a wide variety of materials including most common label stocks. They are generally cheaper than solid dies, but tend to have a shorter life, which makes them more suitable for short run jobs. Flexible dies are usually mounted onto magnetic cylinders, which can cost as much as solid dies, but over time, the combination of magnetic cylinders and flexible dies should be cheaper.

Most cutting systems rely on a blade for the actual cutting and a backing surface to act as an anvil, holding the material in place for the blade to cut through. Most die-cutting options typically expect to use the liner of the label as the anvil, but the growing use of thinner liners can cause issues, particularly at high speeds. Consequently, several vendors offer adjustable anvil cylinders to give better support to the liners.

Flexible dies

There are several suppliers of flexible dies. RotoMetrics, for example, has developed a flexible die specifically for use with digital presses. The DigiNow is a universal digital flexible die with the ability to cut all standard digital pressure sensitive materials. It is meant to work with semi-rotary devices that use an adjustable anvil roller and can cut either paper or film, and any combination of these materials.

Product manager Ulrich Kretzschmar said that it is suitable for all digital label applications, adding, ‘It is truly a universal die that reliably converts all standard materials and combinations available for digital pressure sensitive applications. Specifically engineered to work in combination with a semi-rotary offline digital press equipped with an adjustable anvil, the DigiNow performs right out of the box, minimises set-up time and waste, requires less overage in print production and optimises your die library.’ For now it is available in the US, but will be introduced to other markets.

The RotoRepel coating prevents adhesive from building up on the die

RotoMetrics has another new feature, RotoRepel, a coating for both flexible and solid dies that should help blades last longer by preventing adhesive from building up. The company estimates that dies will last up to four times longer and said that this coating will eliminate flaking and chipping. It is much thinner than other coatings and improves the anti-static properties and allows the dies to be easily cleaned. This also means that dies can be quickly re-used.

Spanish company Lartec manufactures and supplies flexible dies worldwide. The standard dies offer high precision with a maximum variance of just +/-0.003mm. The range includes dies with cutting heights between 0.250 and 0.500mm, which easily covers the 0.440 and 0.480mm heights that are commonly for the self-adhesive label market. They can handle a wide range of materials from papers and films to textile and foils.

Lartec also sells the Altius range, designed specifically to handle thick materials for applications such as RFID labels or multi-layer technical materials for electronics. This series has cutting heights from 0.5 to 1.5mm. Lartec also has dies for different effects, including the Art & Cut series for hot stamping that use special heated magnetic cylinders, as well as for embossing and debossing.

Wink produces the SuperCut range of flexible dies, which can be used with both rotary and flat die-cutting systems. They offer tolerance of +/-0.002mm and die heights from 0.32 to 1.5mm. The SuperCut 90 dies can handle both standard adhesive papers and thermal papers, while the SuperCut 70 dies have a tighter cutting angle and can also cope with films such as PE 85, PP, PET and you can order SuperCut Special dies for unusual materials that might be difficult to cut. There is an option for laser hardening, for cutting filmic materials, or for various coatings to protect against tougher abrasive materials or inks to extend the life of the dies.

Wink showed off a new PerfoPlus system at last year’s Labelexpo. This uses specially developed laser technology to produce very small nicks and perforations with highest precision and reproducibility.

Kocher & Beck also produces a range of flexible dies as well as magnetic cylinders and anvil cylinders. This includes the AI Universal flexible die, suitable for self-adhesive and paper-based labels, as well as thin films. These dies are CNC-sharpened with profile heights from 0.30 to 1.5mm. There’s also a 3L Laser die, which is laser hardened and should last up to three times as long. There are other dies for particular applications, such as the Chrome 24, a hardened die for working with thermal transfer papers.

Die-cutting machines

Many digital presses include their own die-cutting stage. There is a good argument for combining printing and die-cutting on the same machine, particularly for short runs, but for higher volume work, it often makes sense to use a dedicated standalone machine, which can handle the output from multiple printers.

AB Graphic makes the Digicon series 3 integrated finishing machines. This can be configured with a range of processes, including screen-printing and laminating, but its main benefit is the 150m/min speed of its semi-rotary die-cutting unit. ABG also makes the Digicon Lite, which includes semi-rotary die-cutting as well as cold foiling and varnish, and the Digicon 3000, which includes rotary and semi-rotary die-cutting and can be used standalone or inline with an HP Indigo 20000 press.

Bar Graphic Machinery makes the Elite eDSR Easy Load die-cut slitter rewinder. There is a choice of 300, 410 and 450mm web widths, with die-cutting speeds of up to 250m/min. It also makes a complete digital finishing system, the Elite Digiflex, which has a servo re-registration system and includes rotary die-cutting, which runs at speeds of 160m/min.

Daco Solutions makes a number of rotary die-cutting machines. There is the table top DTD250, a compact, cost-effective solution comes with either one or two die-cutting stations, as well as rotary slitting and independent tension control for the unwind/rewind. It can run at up to 150m/min, but Daco also makes bigger machines, such as the DSI, which has a web width of 430mm and runs at 250m/min. There is a choice of up to three rotary die stations.

GM produces several die-cutters including a couple designed specifically for use with digital presses. The DC330, for example, is a semi-rotary label finisher that takes web widths of up to 330mm and substrates from 50 to 200 microns. It can run semi-rotary at 50m/min and full rotary at 72m/min. There are various options, including a laser unit, spot varnish or cold foil, as well as an extra semi-rotary die station. There’s a wider version, the DC500, which takes web widths up to 500mm.

Focus Label Machinery sells the Reflex Servo, designed as an affordable offline finishing system for use with digital label printers. It is a servo-driven system available in 250 and 330mm widths. It includes a rotary die-cutter and a die-sheeter station as well as a dedicated slitting system. There are various options, including a second rotary die-cutting unit as well as inkjet for adding variable data.

Rotoflex sells a number of finishing units, including the DSI die-cutting machine. It’s a fairly versatile machine, incorporating inspection systems as well as slitting. In addition, the die-cutting unit can be disengaged so that it can be run as a slitter/rewinder if necessary. It can run at speeds of up to 305m/min and there is a choice of 330 and 440mm widths and it has a die station anvil size of 381mm, with a die repeat range of 161 to 381mm. The current version uses servo drives, giving it a smaller footprint than its predecessor. It uses Rotoflex’s URC 2 control system.

In conclusion, there’s a wide range of die-cutting options. The choice largely comes down to the volume of work that you need to put through the die-cutter. But it’s also worth bearing in mind that these are robust machines, designed for long life, which will outlast most digital presses.