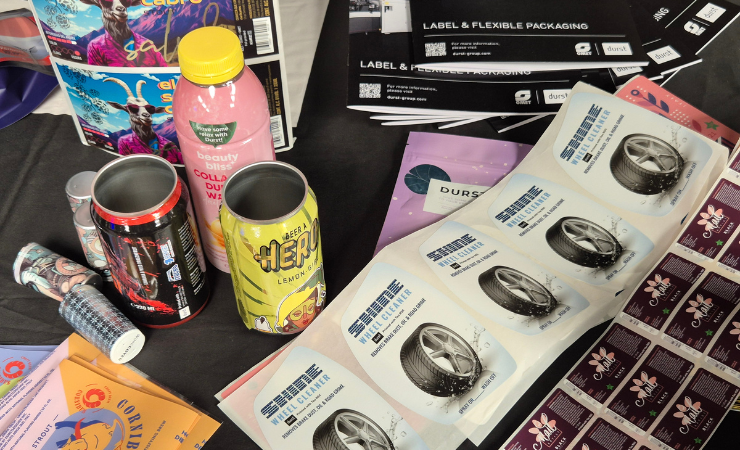

In the sun-soaked Essex town of Brentwood, Bakers opened its doors to the labels and packaging industry to show off the strides it has been making with its latest press installation, the Durst RSC.

There are few things which can draw out a printer from their print room, but the chance to take a sneak-peak of somebody elses’ facility room is sure to do the trick. While the event was held at Bakers’ site in Brentwood, it was very much a joint affair with the Italian press manufacturer, Durst. The Durst delegation gave guests an in-depth account of the developments to its inkjet press.

Thomas Machina, sales director Labels & Flexible Packaging at Durst Group, opened the day with an introduction to Durst Group. For those who do not know Durst’s headquarters is in the remote north Italian mountain town of Brixen, the same place where both the typewriter and the electric engine were invented. As suggested by Mr Macina, perhaps hard work and innovation runs in the DNA of Durst employees.

One such employee, Martin Leitner, head of product management – Labels and Flexible Packaging, showed guests the guise in which that innovation would manifest itself. After a quick review of the inks available on Durst technology (UV, LED and Low Migration), Mr Leitner explained how the company views its development strategy. In the short term, machinery development, takes centre stage. This means working with users to maximise and fine tune current models to their full potential. Medium term development is reserved for printer developments, exploring new ink formulas and such. Long term development is what we all get excited for; technology development, the type of stuff that gets launched at the big industry trade shows.

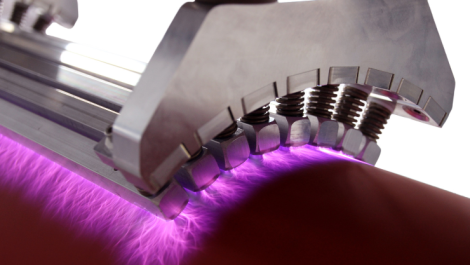

One of the outcomes from this development strategy is the company’s Hawk AI software. The result of 30 engineers specialised in computing and AI. Their work was deemed so important, a whole new business entity was created with the purpose of developing the Hawk AI software. The result was a real-time full width print inspection camera system, which not only detects print defects but acts to fix them in real time.

If the system detects that a nozzle in the print head has suddenly become defective, it can automatically adjust the neighbouring nozzles to compensate for this defect, allowing the press to continue printing with minimal loss of productivity. Bakers became the first site in the UK to install a Durst RSC equipped with the Hawk AI technology, and once the presentations had finished, guests were shown the press in action.

Jamie Godson, technical manager at Baker Labels gave guests a firsthand look at the Durst RSC in action printing two jobs, complete with a live changeover of substrate. As Mr Godson talked the audience through the presentation, he emphasised that the press had enabled the company to improve quality in a consistent fashion and the productivity enhancements from systems such as Hawk AI is the ‘cherry on top’, by providing ‘pain free production’.

Guests were also given a tour around the newest part of the Baker empire, BakPac, the company’s pouch manufacturing division. Pouches are an incredibly popular choice among brands today, however, converting flexible packaging into pouches is a technically challenging process, pushing stress levels higher than those from an Ikea flatpack instruction manual; (as someone firmly on the ‘theoretical’ side of packaging and labels that how it appears to me.)

The BakPac unit contained three Galaxy Packtech pouch makers, with room for another two – which have both been installed in the time between my visit and the publication of this article.

These machines carefully take the roll of printed packaging, fold them over in half, and using a clever combination of materials are sealed with heat after a zip closure is carefully fed into the line, all before being sliced into individual pouches. Simple as that.

The event was a wonderful reminder of the frequency of in-person interactions this industry enjoyed before the pandemic, as well as a great example of two companies working in partnership with each other. The Durst representatives were keen to show that they are an innovative company, drawing on both their heritage and their commitment to technology development. With those developments in the hands of printers such as Bakers, the boundaries of what a label or packaging printer supposedly is, will always be pushed.