If you work with brands in food, beverage, personal care, or household goods, you’ve felt the shift: case packs are no longer stable, predictable formats. Retailers are pushing reduced case pack (RCP) requirements to improve store labor efficiency, optimize shelf turns, and support new hybrid fulfillment models. A case that once held 12 units may now need to hold 10, 8, or even 6, sometimes varying by retailer, region, or promotional cycle.

For converters, that shift isn’t subtle; it’s structural. Each new pack size brings new dimensions, new graphics, new compliance details, and new barcodes. Traditional workflows — preprinted inventory, manual relabeling, separate decorative and functional print processes — simply weren’t built for this level of variability.

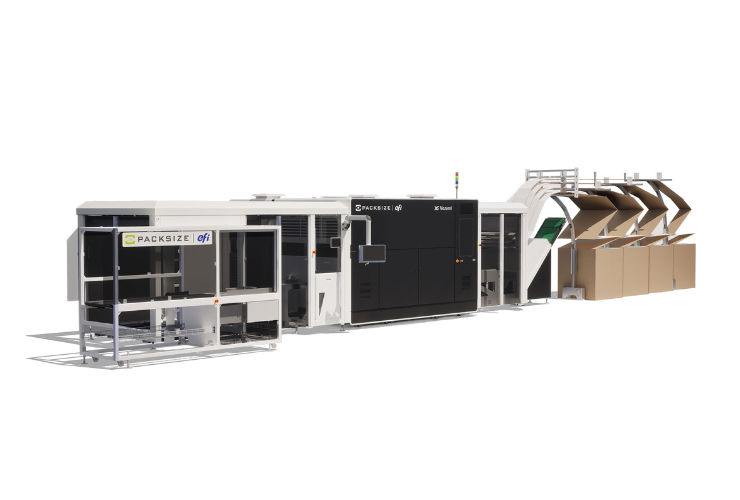

As the industry transitions toward an era of rapid case-size changes and channel-specific artwork, converters need technology that can keep pace. This is where the Packsize® EFI™ X5® Nozomi® is emerging as a pivotal solution, aligning automation, digital print, and on-demand converting in a way that directly supports the demands of RCP.

Why RCP Is Changing the Packaging Playbook

Retailers are reshaping their expectations and packaging is feeling the pressure. Smaller case packs ease in-store labor, fit more efficiently on shelves, and support micro-fulfillment centers as retailers shift toward omnichannel models. Shelf space is more competitive than ever, and tighter modular footprints mean pack sizes must adapt quickly to win the “shelf war.”

Retailers are reshaping their expectations and packaging is feeling the pressure. Smaller case packs ease in-store labor, fit more efficiently on shelves, and support micro-fulfillment centers as retailers shift toward omnichannel models. Shelf space is more competitive than ever, and tighter modular footprints mean pack sizes must adapt quickly to win the “shelf war.”

All of this complexity moves upstream. Brands are now required to produce different case packs for different channels, promotions, seasons, and regions. One product might have five or more case configurations, each with its own print and compliance requirements. This SKU proliferation introduces delays, increases labor, and inflates waste in any workflow that relies on labels, preprinted inventory, or manual changeovers. Simply put, RCP has outgrown legacy production methods.

A Single, Automated Answer: The X5 Nozomi

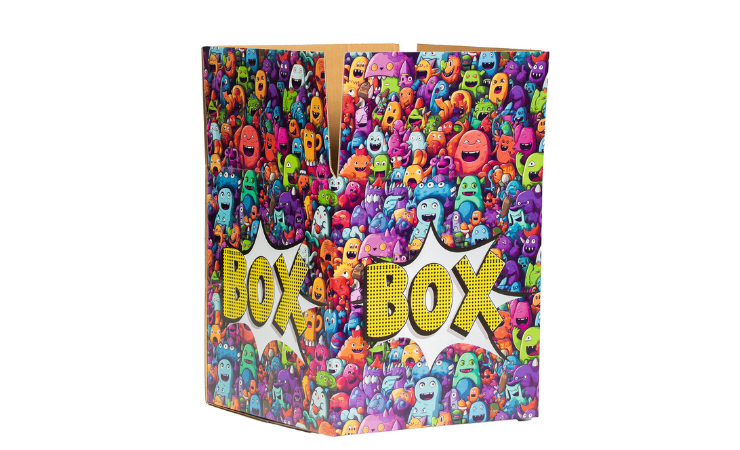

What sets the X5 Nozomi apart in an RCP driven environment is its ability to handle structural, functional, and decorative requirements in one fully automated process. Packsize’s right-sizing and case erecting automation eliminates the need for pre-converted inventory, ensuring every case is produced in exactly the dimensions the retailer requires. EFI’s single-pass Nozomi digital print engine applies full-color graphics – easily incorporating functional data and variable content directly onto the board – before the machine cuts, creases, folds, and glues each finished case.

The result is a continuous, “plain board in, finished branded case out” workflow that can adapt instantly from one pack size or retailer specification to the next. There are no plates, no dies, no stops for label application, and no time-consuming setups. Decorative elements, compliance marks, and scannable data all print in the same pass. For converters accustomed to long changeovers and manual rework, it’s a fundamentally different way of operating.

Where Decorative and Functional Printing Converge

RCP brings with it a unique requirement: decorative printing and functional printing must now happen together. Case counts, GTINs, UPCs, handling instructions, store-specific barcodes, and regional compliance marks change just as frequently as the product graphics themselves. In analog workflows, these elements live in different processes— graphics on the case, functional information on applied labels.

The X5 Nozomi collapses those processes into one. Converters can print high-resolution branding alongside all functional data, dynamically updated for every run, every retailer, and every SKU. A promotional graphic, a club-store layout, a regional QR code, and a retailer specific compliance panel can all change from one job to the next without slowing production.

This integration doesn’t just increase efficiency. It changes what’s possible in case packaging by enabling omnichannel-ready graphics, retailer personalization, and rapid versioning at a scale the market hasn’t seen before.

Responding to SKU Proliferation

With No Downtime With retailers driving rapid change, brands are launching more versions than ever: seasonal programs, regional exclusives, club-store SKUs, e-commerce variants, and small-batch promotional runs. These short runs traditionally disrupt production, forcing converters to choose between profitability and responsiveness.

Digital single-pass print changes that equation. On the X5 Nozomi, short runs, micro-runs, and long runs can move seamlessly across the same line. There are no plates to change or dies to swap, and setup times drop from hours to minutes. Every project — whether 50 cases or 50,000 — can run profitably.

For converters, this new agility becomes a competitive differentiator. For brands, it becomes a reason to bring more work to the converters who can execute RCP quickly and reliably.

Automation Reduces Labor and Eliminates Rework

RCP complexity creates labor strain across nearly every step of traditional workflows. Teams must sort preprinted inventory, apply or replace labels, rework misprinted cases, stage different pack sizes, and manage frequent setup cycles. Each step adds cost and risk.

RCP complexity creates labor strain across nearly every step of traditional workflows. Teams must sort preprinted inventory, apply or replace labels, rework misprinted cases, stage different pack sizes, and manage frequent setup cycles. Each step adds cost and risk.

By integrating right-sizing, digital printing, and automated case erecting, the X5 Nozomi eliminates many of these burdens. Operators no longer manage piles of preprinted cartons or rework mislabeled stock. The system’s automation lets one operator oversee multiple lines, while the digital workflow ensures that every case is accurate, compliant, and retailer-specific—without manual intervention.

In a labor market where skilled converting staff are increasingly difficult to hire and retain, this automation matters.

Retailers Are Redefining the Final Mile — and Packaging Must Keep Up

Today’s final mile isn’t just a delivery challenge; it’s shaping how converters must print and produce cases. Retailers are tightening compliance windows, requiring faster replenishment, and demanding packaging that supports store operations as much as it supports the brand.

Converters must now deliver packaging that is:

- Lighter and easier to handle

- Modular and retailer-specific

- Optimized for shelf visibility

- Fully compliant with retailer scanning systems

- Fresh and variable for promotions

The X5 Nozomi gives converters the tools to adapt, and fast. Instead of fighting the new requirements, converters can embrace RCP as a value-added service that strengthens their position with brands and retailers alike.

The Future of Case Packaging Is Agile, Automated, and On Demand

RCP isn’t a passing trend; it’s the new operating model for retail and consumer goods packaging. With more versioning, shorter runs, and greater retailer influence, converters need a platform that delivers agility without sacrificing speed or quality.

The Packsize EFI X5 Nozomi meets that moment. By uniting right-sizing automation, full-color decorative and functional printing, and fully automated case converting, it enables converters to produce retailer-specific, channel-ready cases on demand —profitably and at scale.

In an era defined by change, those who invest in automated, digitally driven workflows will lead the next chapter of case packaging.

This article is an advertorial; the featured company created the wording and paid for its placement. It has been checked by Whitmar Publications to ensure that it meets our editorial standards.