Software provider Hybrid Software has released version 11.5 of its Packz PDF editor for label and packaging prepress. The update reflects the company’s continued focus on customer-driven development.

Pascal Wybo, product manager at Hybrid Software, said the release incorporates extensive input from Packz users, gathered through suggestions, feature requests, and usability feedback. “This collaborative effort has shaped the development of Packz 11.5, making it a reflection of the needs of our industry,” he said.

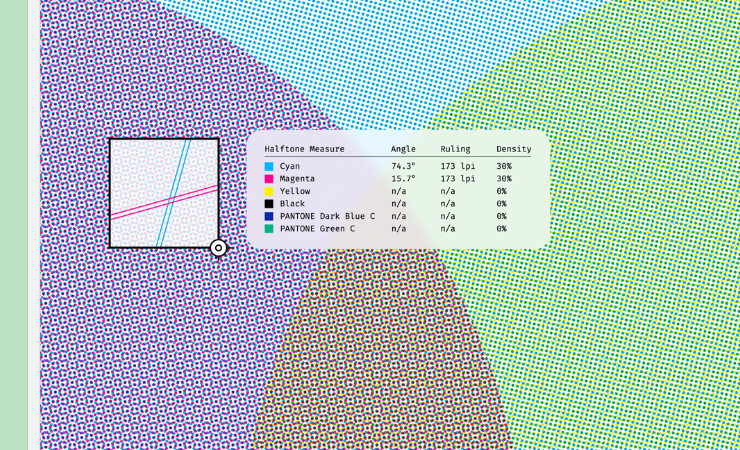

Version 11.5 introduces a Halftone Detection Tool, an extension to Packz Max that uses Harlequin RIP technology to control screening parameters within the editor. The tool is designed to support print professionals by evaluating screen frequency and screen angles from the Packz Max RIP output preview and from any 1-bit TIFF file opened in Packz. It also provides analysis of dot gain compensation, minimum and maximum dot sizes, and plate linearisation.

The release also expands the CF2 format through the introduction of 3D variants, developed in cooperation with Arden Software, Engview, and TreeDiM. These variants allow multiple fold angle configurations – such as closed, open, or flat – to be included within a single CF2 file. They can be rendered in Hybrid Software’s iC3D ray-tracing software and are compatible with structural design systems that support the extended format, explained the company.

Spot colour rendering within Packz has been updated using ColorLogic technology, enabling more accurate on-screen display of spot colours based on spectral or colorimetric data. The improvements affect spot colour tints as well as blends of spot and process colours. Spot colour information is drawn from CxF/X-4 spectral data in PDF files or from selected colour books, and substrate simulation can be enabled through Absolute Colorimetric display settings.

Additionally, the company noted that Packzimizer Laneplanner has been updated to support maximum roll length specifications for roll-fed digital label production. The tool now accounts for exact label roll quantities required by customers, aiming to help converters avoid overproduction and maintain layouts within equipment limits.