Puglia-based label maker relies on Cartes’ modular technology to create analog and digital converting and finishing lines tailored to its business. By Lorenzo Villa

L’Immagine was founded in 1980 in Molfetta, Bari province, Italy, by a group of friends who, having f inished their studies, aimed to achieve economic independence. Born amid the economic crisis and new social demands of the 1970s, the company was set up as a cooperative with equal contributions from its young members, who worked as technicians or laborers to finance their first screen-printing press. Among them was Stefano Salvemini, a photography enthusiast who championed screen printing as a way to experiment with and reproduce images on paper, plastic, and other objects. In the following years, in part because of inexperience, some partners gave up, but L’Immagine grew and invested in a single-color offset press to launch a publishing division. Growth accelerated in the 1990s, encouraging the purchase of multicolor offset presses, used chiefly for glue applied labels for the wine, oil, and food sectors. In 2000, during the self-adhesive label boom, L’Immagine invested in a narrow-web flexo press and by 2012 had entirely phased out sheetfed offset. In 2015, concurrent with installing an HP Indigo press, the converter turned to Cartes for a finishing line featuring screen printing, hot stamping, and laser die-cutting. To boost efficiency, the Puglia-based company added an HP Indigo 6K in 2022, as well as a Cartes GT360 line with a Jet D-Screen unit and a latest-generation laser. As of February 2025, Etichette L’Immagine is part of the international Tikedo group.

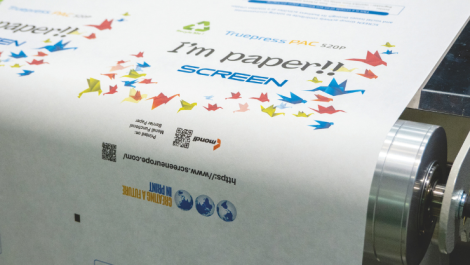

The digital printing, finishing, and embellishment department at Etichette L’Immagine

Manufacturing partner of just-in-time exporters

Etichette L’Immagine serves a diverse clientele, including small and medium-sized producers of fine wines, olive oil, and local food products, many of whom are export-oriented. Most commission sophisticated labels printed on specialty papers and embellished with foil, spot varnish, metal doming hot-foil effects, and embossing.

“To ship their products worldwide, our customers ask us for premium labels, produced quickly, in the exact required quantity, in a specific language and at a reasonable price,” said Stefano Salvemini, CEO of Etichette L’Immagine. “Printing them in offset and converting them offline would take ages and drive up costs, so we decided to invest in carving out our own unique space.”

L’Immagine also serves pet-food producers and manufacturing companies across various sectors. Its products range from the simplest labels, printed in high volumes with high-definition UV flexo technology, to more sophisticated labels, digitally printed on uncoated and cotton stocks, enriched with commissioned artwork and a remarkable variety of embellishments.

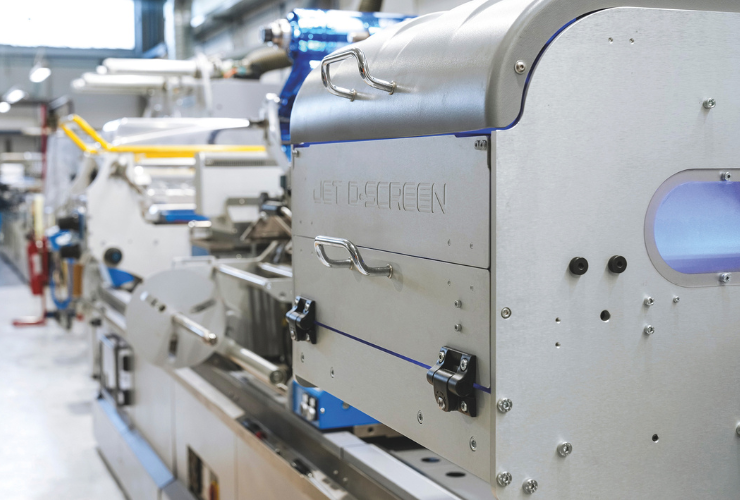

The Cartes GT360 line from Etichette L’Immagine integrates analog and digital finishing and converting modules, including the Jet D-Screen inkjet unit and laser die cutting

Along with digital printing, seen as the only viable option for handling heterogeneous, fragmented orders, Salvemini questioned how to make post-printing processing more streamlined and efficient. It was on this challenge that the paths of Etichette L’Immagine and Cartes met a decade ago, never to be separated again.

GT360: The scalable embellishment that “speaks digital”

In 2015, L’Immagine configured its first Cartes line with screen printing, hot stamping, and semi-rotary die-cutting: three basic ingredients that in the following years proved ideal for mid-complexity embellishment. At the same time, it decided to approach laser die-cutting, launched by Cartes in 1999 but still uncommon among traditional label converters. Seven years later, the converter built on its experience and decided to raise the bar significantly, commissioning Cartes to supply a GT360 line equipped with a flexo varnishing unit, screen printing, hot-foil stamping, Jet D-Screen inkjet varnishing, semi-rotary die-cutting, high-performance laser die-cutting, and metal doming.

“Combining analog and digital in the same equipment may seem bizarre, but having the best of both worlds in line gives us many advantages,” Salvemini said. “First, we can effectively handle both low and high runs on the same machine, without bottlenecks. Also, by using all the units together, we can create extraordinary labels in a single pass, drastically reducing waste and makeready time.”

Being able to choose the digital process, the analog process, or a combination of both has translated into operational, economic, commercial, and logistical benefits for L’Immagine, which uses the GT360 line full time for all its work, thus speeding up equipment payback and reducing floor space, variables, and the number of operators involved.

Jet D-Screen and in-line laser: digital game changers from Cartes

In its technology-scouting journey, Etichette L’Immagine analyzed multiple suppliers of digital die-cutting and embellishment and concluded that only Cartes had a platform advanced enough to integrate any analog or digital process in line. The new generation of lasers also solved the minor quality flaws that had previously drew criticism from die-cutting purists.

“The only alternative to GT360 would have been to have multiple machines to do the various processes, making many jobs uneconomical,” Salvemini said. “Neither Jet D-Screen nor laser will completely replace traditional screen printing and die-cutting, but today they are mature, reliable technologies and a formidable weapon for delivering jobs within hours rather than days.”

Labels created by L’Immagine with GT360

Thanks to its modular architecture, GT360 is ready for the integration of new units, existing or yet to be released, that will enable Etichette L’Immagine to create increasingly sophisticated products while safeguarding its investment.

New technical opportunities for new products and markets

The combination of digital printing, Jet D-Screen, and laser die-cutting enables Etichette L’Immagine to bring to life products that were previously impossible to produce economically. Thanks to digital screen printing, the company can create in a single step embellished labels with raised varnish and foil of different heights, as well as extremely fine, detailed text and patterns that would be impossible to render with screen printing. In addition, because no tooling, such as screens, clichés, or dies, is required, last-minute changes can be made during the run, and virtually unlimited variations can be produced without extra equipment costs.

“For the launch of a new product at the last Vinitaly, one of our client’s agencies proposed six labels that differed in artwork, embellishment, and shape, and they took a long time to decide which one was the best,” Salvemini said. “So, we offered to make them all and present them at the show, letting the clients decide which one was the most appealing”

Stefano Salvemini, center, between Ivan Spina and Enrica Lodi of Cartes

Leveraging its expertise and a unique mix of technologies, Etichette L’Immagine aims to make the production of embellished labels with variable layouts easier and more affordable. Thanks in part to its partnership with Cartes, the company has built a singular value proposition, based on listening and accommodating its customers’ technical, creative, economic, and logistical needs.

“When we approached GT360, we didn’t start with the idea of buying a machine, but with the kind of service we wanted to offer our customers,” Salvemini said. “Thanks to its innovative technologies and an exceptional team, Cartes has created a machine that perfectly aligns with our business model, which will become increasingly digital.”