Competitive brands will push for labels with striking colours, complex designs, and increasingly high print resolutions that attempt to instantly signal quality. How do the presses of today meet these demands?

In the label converting industry, the way your label looks on a crowded shelf matters. Consumers will scan a shelf and make their decision on what to buy in seconds.

For converters, there then appears to be a continual need to invest in label printing equipment that can deliver labels that pop off the shelf.

Yet eye-catching labels are just one dimension of the final product. The key question for label converters and brands to consider is – how much will the market pay for a product? If the extra cost of elaborately designed label output inflates the unit price beyond what purchasing managers accept, orders will diminish. Converters must then consider how to achieve the highest quality that remains economical and cost-effective.

At a glance, a simple measure of label printing quality is to consider the dots-per-inch (DPI) resolution of printing equipment. And while the resolution is an important consideration of overall label production, it is only one factor in how a label looks and whether it appeals to brands and consumers—as most shoppers never observe the difference between different DPI resolutions after a certain threshold.

A neuromarketing study by UPM Rataflac confirmed that consumers subconsciously consider a variety of factors when observing a label including: colour gamut, substrates and designs featuring tactile effects and textures, and contrasts between different design elements.

Crucially, these elements work in concert; no single detail is persuasive in isolation. For converters, these findings reinforce that consistent output using reasonable DPI resolution with vivid label design offers far greater commercial value than a press tuned for maximum DPI at the expense of flexibility or productive efficiency.

Carlo Sammarco, business development director for Label, Screen Europe, said: “Success in today’s label converting sector requires more than an individual exceptional label produced on the showroom floor; it calls for a seamlessly integrated digital printing workflow where highly formulated UV ink, advanced workflow management software, and an overall focus on production efficiency.

“Our Truepress LABEL 350UV SAI digital UV inkjet label printing solutions are one tool that provide label converting businesses a practical route to higher turnover and stronger margins with advanced technological inkjet innovations from a long history in the label printing market.

“In an industry where product lifecycles are shortening and SKU counts keep rising, a converter equipped with Screen digital inkjet can expect a production environment primed for growth—one where efficiency drives profitability, and lasting commercial success comes through consistent printing quality and productivity.”

Productivity for ROI

Defining return on investment for label and packaging printing equipment as a whole is challenging because every converter has a unique job portfolio that contributes to their bottom line.

Mark Andy’s Digital One positions itself as an entry-level hybrid press for micro to short-run prime label applications, combining affordability with inline finishing capabilities.

The compact system delivers four-colour electrophotographic printing at 1200dpi using dry toner technology on a click charge-free model, the press targets converters seeking profitable short-run solutions without substantial capital investment.

The hybrid configuration integrates digital printing with inline converting and finishing, simplifying workflow for smaller production volumes where traditional flexographic setups prove uneconomical.

A more productive hybrid can be found in the Mark Andy DSHD HIGHSPEED 1200. Available in 1330mm and 430mm, the new HighSpeed 1200 model is capable of 46m/min in up to eight digital colours at 1200dpi, and with the digital engine installed anywhere in the servo-driven flexo platform of the Performance Series.

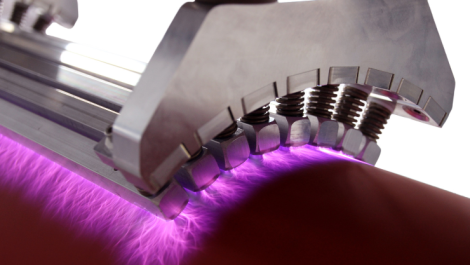

Screen’s Truepress Label 350UV SAI S press

Considering again the need for label printers to find an ROI on any investment, how can you respond to customer requests for premium materials, embellishments, and finishing – which can impact print throughput by slowing down line speeds, with a chance that added-value labels produced may not yield higher profit margins. Plus, local energy, labour, and material costs will always vary.

Michael Matthews, product manager – DP Colour, Domino Printing Sciences, explained: “We have seen several developments over the last five years that can help accelerate the payback for converters across the board, as they address some of the key issues every converter faces.”

Improving printing productivity and efficiency is one of them. Mr Matthews continued: “From a Domino point of view, we have recently released a new high-speed productivity mode for the Domino N730i digital label press, increasing printing speeds to up to 90m/min. This provides a significant productivity boost of up to 28% or a reduction of up to 22% in production time, with no perceptible difference in print quality compared to the standard operating mode. The print quality adjustment supports an annual ink saving of up to 8%, enabling converters to save thousands.

One for the future?

Canon is tantalising the industry with the forthcoming launch of the LabelStream LS2000, marking the company’s entry into the label printing sector with a focus on sustainability and food safety compliance.

Built on Canon’s Qualinx inkjet technology, the water-based system offers five-colour printing (CMYK plus white) at speeds up to 40m/ min across a 340mm maximum web width. The press targets label converters seeking reliable, environmentally conscious production capabilities without compromising operational simplicity.

The LS2000’s water-based inks meet multiple food safety standards, positioning it for exterior food packaging applications across sectors including beverages, personal care, household goods, and electronics. This compliance addresses growing regulatory requirements whilst supporting converters’ sustainability objectives.

The LS2000 represents Canon’s strategic move into industrial label printing, leveraging established inkjet expertise to address market demand for sustainable, food-safe digital solutions.

“Print quality perception remains paramount for converters, with many of our customers rating quality output as more important than speed. They aim to provide an excellent service to their customers, and being able to print striking artwork at 1200dpi is part of this. Developments in printheads, such as our Brother BitstarTM printhead, designed specifically for the label industry, can make a significant difference.

“Lastly, there is time. The more time a press is running, the more labels are printed for customers, so set-up speed can make a big difference. Where flexo might take an hour to set up, digital can be ready in minutes, making shorter runs more feasible and opening up new market opportunities.”

Many press providers have accelerated their digital pre-press processing capabilities over the last couple of years. Now, AI-enabled software innovations, such as the latest version of Domino’s Sunrise DFE, drive even faster pre-press processing, with real-time, in-line RIP of artwork files, maximising production time and contributing to a quicker payback.

Mr Matthews concluded: “Bridging flexo and digital technology, we offer hybrid printing, combining the best of both worlds in a single-pass process, which provides higher competitiveness compared to pure flexo production. Here, modular hybrid printing and finishing technology enables converters to reconfigure processes more easily as brand demands change, with print engines like the Domino N730i Integration Module designed to support easy integration into any flexo processes.”

Industrial thinking

At a time when speed, flexibility, and quality are critical, Durst Group is positioning inkjet as a true mass production technology — not just for short runs, but for full-scale industrial output.

A big part of this is down to the press holding printing speeds of up to 100 m/min across web widths of up to 510mm, giving converters the parameters need to scale.

Thomas Macina, director global sales labels and flexible packaging at Durst Group, said: “Thanks to proven printhead and electronics technology, Durst solutions offer unmatched reliability, ensuring consistent uptime even in demanding environments. Meanwhile, innovations like Hawk AI, automatic register control, automated maintenance, and AI-powered workflow automation provide a new level of simplicity — reducing operator workload while maximising output quality.

“Our core values of reliability, simplicity and performance are more than slogans,” said Mr Macina. “They are the foundation of our production excellence and customer partnerships.”

While labels remain the core target, interest in non-label applications like folding boxes is growing rapidly. Durst now leads global sales, service, and support for these hybrid lines, ensuring a single point of contact worldwide.

“Inkjet is no longer an emerging alternative — it’s a proven industrial solution,” Mr Macina concluded. “Durst has built platforms that redefine digital print, allowing converters to scale with confidence and expand into new markets.”

Modularity

No two label printers are the same and so for some press manufacturers, the emphasis has come down to creating systems which were modular, and therefore customisable to the needs of the converter.

Bobst is one such company and offers its DIGITAL MASTER series platform, this all-digital label solution can be bought as a standalone printer or built in combination with a variety of units, depending on how much additonal work needs to be done inline.

The dFlex inkjet system from UK manufacturer Focus Label Machinery, offers manufacturers the capability to handle small-volume orders and variable data applications.

Operating at production speeds of 20-70 m/min, this system delivers four-colour printing plus white ink options, making it ideal for brands requiring vibrant, high-quality labels without the traditional constraints of large minimum order quantities. The integration of inkjet technology with a flexographic print station creates a hybrid solution that combines the best of both worlds—digital flexibility with conventional finishing capabilities.

The system’s servo technology ensures precise registration and consistent quality across various web widths, while UV drying systems enable immediate handling and finishing. This streamlined approach allows for complete label production, from printing through coating and converting, all within a single pass operation.

Applications span across multiple sectors, including standard labelling, security labels, packaging, and ticketing solutions. The roll-to roll and roll-to-sheet converting options provide additional flexibility for diverse customer requirements.

The essential goal of a successful converter is supply labels customers can afford, consumers want, and that business can make profit from. Fit-for-purpose digital printing, finely tuned for consistent output and attractive economics, fulfils this requirement and sets the stage for sustainable growth.