Handling artwork origination for over 2000 brands including household names such as P&G, Unilever and Nestlé, Trident has brought to life the designs for some of the most iconic packaging displays in the last 20 years.

While Trident began life as a print services provider, it has evolved into a global artwork and brand management company, handling print ready artwork for some of the biggest brands all over the world. To do this properly requires a global footprint, and with 13 offices globally and seven production sites across Asia, Europe and America, Trident is in a unique position of being able to work on a client’s request across an entire day (almost).

However, there is much more to Trident than simply getting artwork fit for print production, as a brand management service there are many prongs to its fork. Design is a huge part of the company’s business, although it is done separately at its sister company Grit & Pearl, which champions its background in origination to assure any design created by them, will fly through any artwork approval process.

With digital displays playing a large part of any business, the company also has expertise in CGI design, bringing 2D designs to life on screen by creating a realistic digital 3D product – across multiple SKUs – allowing clients to see their brand on any shape container or package.

However, as we know life cannot be contained to a computer screen, and for many of Trident’s clients, they want to see what that new packaging design will look like, in the ‘flesh’.

Bringing designs to life

While the print production floor might be dramatically smaller than your average print services provider, what they lack in capacity they more than make up for in creativity; creating beautiful and ultra realistic packaging proofs.

Adam Nyland, global samples technical SME, said: “More and more now customers don’t just want a facsimile of what they’re going to see – they want the real thing. We have to match what they’re going to see in final production.”

Zen the in-house developed online approval system which the company also uses for its internal workflow

That’s where the three-man digital production team come into their own. “We will very often get a call from a client asking us for a mock up to be ready in 24 hours. In some cases, they’ve organised a photoshoot but have forgotten that the product doesn’t yet exist beyond a computer screen.”

To get that finished product requires a cross departmental cooperation. “We work with pretty much everybody in the business as well, especially CGI, many people assume that we work at cross-purposes – they believe if you have a digital 3D mock up, you don’t need a physical something, well I can assure you; you absolutely do.

We work closely with the design team, so if you’ve got designs going through and you want to see what they look like as they’re being developed we can jump in there, and then also with the artwork teams in general we will speak to all of them all the time so we we’ve got our hands in a lot of pies a lot of the time.”

The right press for the right job

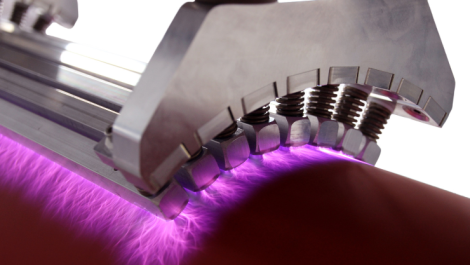

The company produces all its work on two digital printing presses, a Roland LEC and an HP Indigo 7000 press. The Roland printer handles materials up to a meter wide with unlimited length, though the team typically runs at 800mm to optimise cutting bed integration. Its automated queuing system allows multiple jobs to run unattended—a capability that has transformed operations. “It was like getting a new member of the team,” explains the production manager. “We can set it to run and go off to handle other tasks.”

While the company wasn’t committed to HP specifically, the Indigo 7000 proved the optimal choice for their production needs. Running CMYK standard with premium white capability, it delivers superior opacity levels. The press excels at inline embossing, laying ink on impression paper and embossing from one side in a single pass. For more intricate work requiring greater depth, additional embossing options are available, including tactile clear inks that layer beautifully for labels.

The team’s production skills are so refined that monthly competitions challenge staff to distinguish their packaging reproductions from store bought originals—a testament to their precision. Yet these impressive print reproductions represent just one end of the comprehensive service Trident provides clients.

Print ready files

Jason Larard, global colour manager, explained: “We have the creative design at the very start of a process which leads onto full project management; artwork and pre-press, and colour management. We ensure that all correct data is going to the printer. All choreographed by our own in-house artwork management system, Zen. Zen is an online approval system which we also use for our internal workflow, but there’s also bits of automation built into too.

“We also offer business analysis too. Some of our customers using us for artwork, are often trying to figure out other problems as well. They might be working with another system for instance and so they’ll need our help with implementation or looking at new ways of working and better processes, because they know we’ve worked in this industry for so long, we often get involved at their end to help them manage their own processes better and suggest new ways of working.”

Every company is different and so every customer comes to Trident with different needs, some are very organised, whiles others are not quite so put together.

“What we say to our clients is, get us involved as early as you possibly can in the process, even if you don’t know who the printer’s going to be,” continued Mr Larard. “We’ll look at that and think, it’s a shrink sleeve, it’s going to be flexible, we can give you some input into that, where the challenges might be, where you might need to go, and where you might need to make a compromise.

“If there’s something really critical that we think actually we’re not 100% sure how this is going to look, we recommend you go to an on press trial. If it’s a flexo label with a fade off to white, we’ll look at different ways of disguising the hard edge so we might run the vignette all the way off the label. We’ll just fill it with all the different options we can get, as close to the design intent as we think the client wants to see, but with respect to the print process.

“Once the print feasibility is done, we say, right, the design is locked at this stage. Our CSR team will look at it and say, is everything clear? Do I understand what the client wants here? Do I have everything we need? We’re looking for anything that’d stop us basically creating an artwork that’d be right the first time.

“Our artists aren’t just making it fit for content, so basically everything the client’s asked for, they’re also making it fit for purpose, so everything the printer needs to be able to print that job. The benefits of us doing that in one stage is that we’ve already looked at the artwork and made any print adjustments that are needed. So, if the client does approve it first time, it’s ready to go to the printer straight away.”

As a business concept, vertical integration is a sound strategy and one which Trident has implemented seamlessly by being able to walk their clients through multiple stages of prepress with expertise and flair. Its production capabilities give life to boardroom concepts, turning them into tangible prototypes, enabling informed decision-making before a full-scale rollout.