The long-awaited water-based inkjet press is set to revolutionise packaging printing.

At an exclusive event for packaging converters and print service providers, Agfa, a leading manufacturer of innovative printing solutions, officially unveiled its pioneering SpeedSet 1060 inkjet printing press for the packaging market.

The event took place at Agfa’s Cambridge manufacturing facility, where the company’s packaging and inkjet technology specialists highlighted the capability of the SpeedSet 1060 sheet-fed digital press to meet short-run packaging needs while setting new benchmarks in printing performance and efficiency.

Press specs

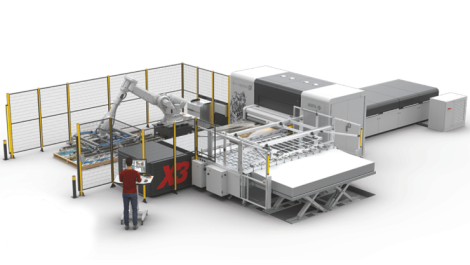

SpeedSet 1060 is a high-speed, sheet-fed and water-based inkjet printer for the packaging market. The headline statistic for the press is an unmatched speed of 11,000 B1 sheets per hour. This makes it the fastest digital press available for packaging.

The press can handle media from 0.2mm paper up to 2mm microflute, with this media range making the press suitable for applications such as retail- or shelf-ready food and beverage packaging.

A proprietary ‘floating’ steel vacuum conveyor belt moving at 150m/min is critical to achieving the press’ top speed as well as ensuring sheets are positioned correctly and held in place when travelling through the inkjet engine, before being handed off to the Natgraph drying unit. Mabeg systems are used to feed the press and stack printed sheets. Agfa’s Asanti workflow software is used to run SpeedSet 1060, having been developed and honed in the sign and display market where Agfa has a strong and established heritage.

The inkjet engine can be configured with up to seven colours, although the demo machine is configured with four. With a resolution of 1200dpi, SpeedSet delivers sharp text and has an extensive colour gamut that meets industry standards. A digital priming unit and two digital varnish stations bring the number of possible on-press modules for jetting consumables up to 10, when fully configured. The press is fed by 200-litre barrels, although the possibility of integrating with an ink farm is being considered, depending on the specifics of those converters looking at adopting the press. With all consumables water-based, they are stated as being environmentally friendly and in compliance with food-safety regulations. Adding to the sustainability credentials is the fact that digital printing minimises waste of media and consumables.

USPs

Digital application of a water-based primer with a very low wet thickness enhances image quality, expands the colour gamut and decreases ink consumption. This not only leads to cost savings, but also reduces environmental impact. Digital printing of both primer and varnish allows for selective application only where needed.

When it comes to production, with digital printing’s ‘right f irst time’ advantage, start-up is swift and job switching is effortless. This quick turnaround supports on-demand printing and is great for getting diverse packaging designs to the shelf in no time. In addition, SpeedSet printing offers significant cost advantages over offset printing. It boasts shorter setup times, reduced material waste and efficient variable data printing, while colour separations are not needed and maintenance expenses are lower.

Being a fully digital solution enables customisation or personalisation of each individual print, facilitating product differentiation. Machine utilisation is also enhanced, as SpeedSet can print all runs up to around 5000 sheets more cost-effectively, allowing printers to focus their offset litho operations on longer print runs, thus making it more efficient.

Go-to-market

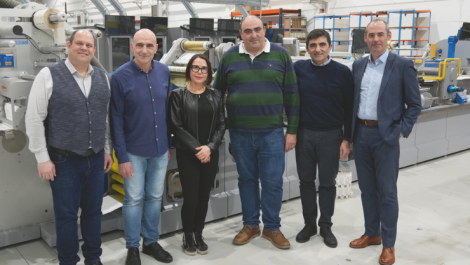

A two-day launch event to officially unveil the press was attended by converters – many of whom were involved in the development of the press – as well as analysts, the trade media and industry consultants.

Prior to the unveiling of the press in the steel, industry experts discussed trends in packaging and retail-ready solutions, providing valuable insights into staying ahead in the dynamic packaging industry. This led into a live demonstration of SpeedSet 1060, provided those in attendance with an up-close look at the technology and showcased the press revolutionary speed and unmatched print quality.

The event not only served as a platform for industry professionals to explore the transformative potential of SpeedSet 1060, but also offered insights into the engineering excellence behind the printing press, provided the opportunity to engage with specialists, inspect print samples and facilitated meaningful discussions with fellow professionals about the possibilities and future of digital packaging printing.

‘SpeedSet is set to be a game-changer in the packaging printing market,’ says Matt Brooks, head of packaging at Agfa. ‘This fully digital packaging printing press merges the robustness and print excellence of an offset press with the compelling attributes of inkjet printing. It offers offset like print quality yet boasts shorter setup times, reduced material waste, and efficient variable data printing. On top of that, with its killer speed of 11,000 B1 sheets per hour, it is simply the fastest digital packaging press around. It will enable packaging converters to make their current operations more efficient. Print runs up to 5000 will be cheaper on the SpeedSet.’

Agfa is currently finetuning the SpeedSet in collaboration with several early adopters. Those early adopters form the f irst customer funnel and were called upon throughout the development of the press over a number of years to have it ready and raring to go. The first installations are expected by the end of 2024, with a ramping up of adoption in 2025 and 2026.