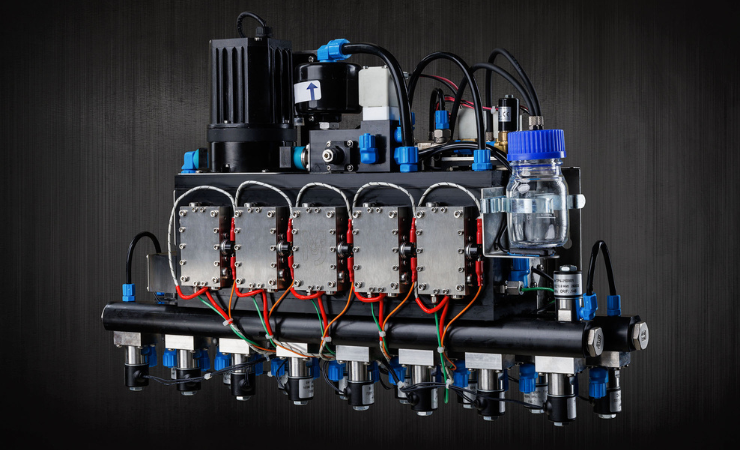

Fluid management specialist Megnajet has introduced a new addition to its JetSource product range, the JetSource HFR, a high-volume fluid management system developed to meet the demands of wider, multi-printhead inkjet applications.

Designed for OEMs and system integrators operating in large-scale, high-duty environments, the JetSource HFR features a two-litre fluid capacity and expanded printhead connectivity. The system is built to provide continuous fluid delivery, making it suitable for high-output processes such as label, web, roll-to-roll, and scanning applications.

The JetSource HFR follows the 2023 launch of the JetSource Core system, which supports up to five fluid paths. The new model increases this capacity to between six and eight paths, allowing for up to four litres of fluid recirculation. This makes it particularly useful for bar-based print systems or applications requiring broader coverage, explained the company.

Key features include over 900 watts of heating power for rapid system warm-up and precise temperature control via dual heating and sensing components. These capabilities support consistent output and reduce delays during startup. An internal bypass system allows the full fluid volume to circulate and heat evenly throughout the unit.

Megnajet has also integrated venturi-based meniscus control – a pressure regulation system used across its JetSource range – into the HFR. Megnajet said this ensures reliable fluid ejection, even under demanding print conditions.

According to Megnajet general manager Mike Seal, the HFR system was developed in response to customer requirements for dependable, high-performance fluid management. “We developed the JetSource HFR to address our customers’ needs for precise fluid control and conditioning for high-productivity applications,” Mr Seal said. “This enables OEMs to focus on their core operations without needing to develop in-house systems.”