Italian label converter Etikmar has installed a new hybrid production line centred around Screen’s Truepress Label 350UV SAI-S digital inkjet press, and Lombardi flexo print units. The investment is a response to rising market demands for shorter print runs, versioned products, and quicker turnaround times, particularly in the food, retail, and personal care sectors.

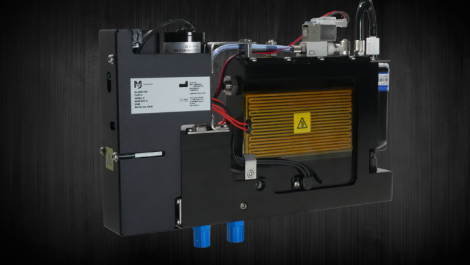

Following the success of its existing Truepress Label 350UV SAI-E, Etikmar opted to deepen its partnership with Screen by choosing the SAI-S model. This upgraded version offers a wider colour gamut with the addition of orange and blue inks, improved Pantone matching, and faster print speeds.

The digital press is integrated into a complete end-to-end label production workflow that includes two Lombardi flexographic print stations, a high-speed Volo semi-rotary die-cutter, and an inline waste removal system. This setup allows Etikmar to switch between digital and flexo printing, optimising production based on job length and complexity.

“The ability to produce multiple versions and finish jobs inline with the same die gives us a competitive edge,” said Alessandro Marani, sales manager at Etikmar. “We can meet the demand for fast, flexible delivery with fewer production steps and reduced lead times.”

Using digital inkjet for short runs and flexo for longer ones, Etikmar has been able to reduce production costs while maintaining high quality. Screen said the hybrid workflow eliminates the need for plates and lengthy setup processes, improving speed and efficiency.

Mr Marani concluded: “Hybrid digital printing is a turning point for our business. It improves accuracy, reduces waste, and ensures we meet our customers’ expectations for fast, flexible, and vibrant label production.”