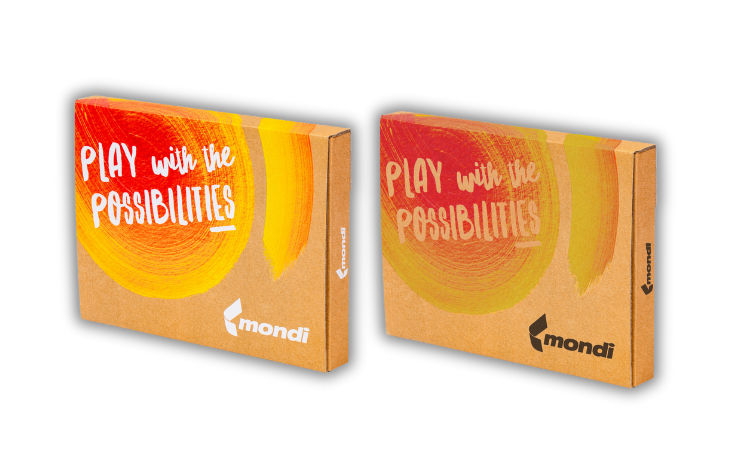

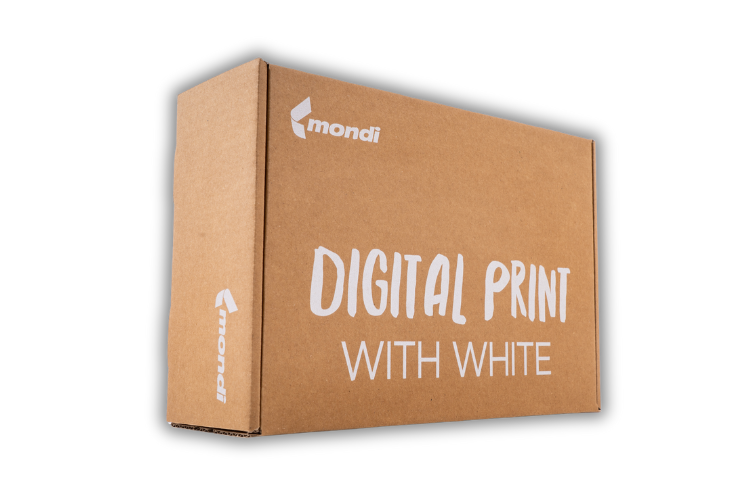

Mondi has expanded its six-colour digital printing capabilities for corrugated packaging by introducing white ink as a standard option. The addition supports a growing market demand for high-contrast, brand-specific designs printed directly on brown corrugated board.

The new white underprint function enables more vivid colours, logos, and graphics to appear with increased clarity and visibility – an important factor for maintaining brand consistency, particularly in retail and eCommerce environments where shelf impact is crucial, explained the company.

The new white underprint function enables more vivid colours, logos, and graphics to appear with increased clarity and visibility – an important factor for maintaining brand consistency, particularly in retail and eCommerce environments where shelf impact is crucial, explained the company.

Mondi’s digital printing process uses water-based inks, approved by Swiss Quality Testing Services (SQTS) for use on primary packaging. The absence of traditional printing plates or clichés allows faster set-up times and greater flexibility for design changes, making the process suitable for seasonal or regional variations, or promotional campaigns.

Additional capabilities such as halftone printing allow for smooth gradients and three-dimensional effects, enabling high-quality packaging aesthetics without increasing material usage.

Another practical feature of the digital process, according to Mondi, is the ability to print variable data, such as sequential barcodes, EAN codes, or QR codes, directly onto the corrugated board. This reduces the need for additional labelling, lowers the risk of scanning errors, and cuts associated costs.

The technology is capable of printing on both white and brown surfaces, as well as on open flutes, with the flexibility to handle medium to large order volumes. Orders can also be split into multiple print variations without impacting production efficiency, helping reduce inventory surpluses and warehousing costs.

The expansion of the printing range aligns with Mondi’s broader goals of delivering resource-efficient packaging solutions across key industries including food and beverage, FMCG, and eCommerce.