Los Angeles-based label printer, Cover Label, has installed the Domino N730i digital UV inkjet label press to accelerate growth, expand production capabilities.

This decision marks a strategic move forward for the label converter, which has grown from a modest flexographic print shop into a multi-technology print house serving the food and beverage, cosmetics, health, and other consumer packaged goods industries.

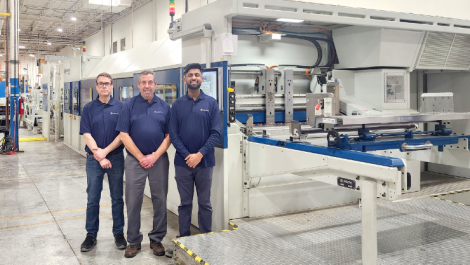

Cover Label operates with a team of under 20 employees across staggered shifts, running one Domino digital press and four flexographic presses: a 17″ Nilpeter FA7, a 13″ Mark Andy 2200, a 7″ Mark Andy 2200, and a Webtron 7550. Finishing capabilities include a Grafotronic laser die cutter. “Fast turnaround, excellent service, and technical capability are our trademarks,” said Co-CEO Pat Wafer. “We serve customers who value speed, reliability, and standout embellishments like foils and spot UV.”

Digital printing has become central to Cover Label’s value proposition. The Domino digital press didn’t just serve short runs—it opened new doors. “We saw multi-SKU work driving demand,” says Pat. “Having digital allowed us to win customers who later gave us flexo work, too.”

Their business has been growing at such a fast pace, Cover Label decided to transition to the Domino N730i. The decision was driven by three key factors: speed, resolution, and efficiency. “We went from 600 dpi to 1200 dpi, and from 25–30 meters per minute on the N610i, to 60–70 meters per minute on the N730i,” said Mr Wafer. “That alone doubled our capacity. The improved resolution also lets us print small text and fine gradients with unmatched clarity.” With enhanced capacity, Cover Label has shifted longer jobs to digital.

The Domino N730i also created new workflow opportunities. “We noticed our finishing equipment couldn’t keep up,” says Pat. “We’re now adding a semi-rotary die cutter to complement the laser system.”

Customer feedback has been positive, even if not formally solicited. “We have a health & beauty customer with fine four-color process text that we struggled to run well on flexo,” says Ryder. “With the N730i, we delivered digitally printed samples that were spot on. That job is now fully digital.”