Bobst has announced updates to its ExpertFold 145/165 folder-gluer, introducing an automated blank aligner, expanded support for fully digital job processing, and a new Recipe Management Workflow. The company has also added two new machine formats, 106 and 215, designed to address specific production requirements.

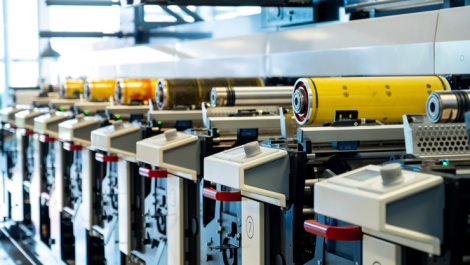

The ExpertFold range is built around a modular concept intended to accommodate different customer needs based on market segment, production volume, and plant size. The machines are designed for folding and gluing corrugated board and litho-laminated packaging, with features aimed at maintaining transport stability, folding accuracy, and consistent gluing quality, explained Bobst.

The updated ExpertFold 145/165 includes the Sphere human-machine interface, which connects to the Bobst Connect platform. This allows job data to be prepared remotely and production data to be accessed centrally. According to the company, this enables converters to monitor performance across multiple sites, generate production reports, and plan shifts more efficiently.

The addition of the automated blank aligner, combined with existing Matic automation features, is intended to reduce setup time and operator workload while improving setup precision.

Bobst has previously introduced a specialised e-commerce configuration for the ExpertFold 165, incorporating PolyVacuum and GyroBox modules for inline application of self-adhesive tapes and opening features. Building on this, the company has now introduced two new machine widths.

The ExpertFold 106 is designed for smaller micro-flute boxes and features a reduced machine width to minimise floor space requirements, while retaining the core technologies of the larger models.

The ExpertFold 215 targets large-format applications, with the ability to handle blanks up to 2300mm wide. It includes an extended feeder, a 6000mm folding section, and a 6600mm delivery section. The machine is available with or without a pre-breaker and can be configured with PolyVacuum and GyroBox XL modules for producing complex boxes in a single pass.

Bobst said the expanded ExpertFold portfolio is intended to give converters more options when selecting equipment and reflects growing demand for high-end micro-flute packaging and large e-commerce box formats.