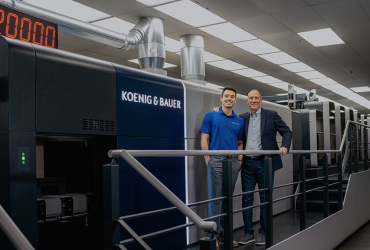

Koenig & Bauer Kyana has enabled Pennsylvania-based Grafika Printing to achieve full production visibility by integrating a third-party press into its digital ecosystem for the first time.

Using the IIoT gateway Kyana Connect, Grafika can now securely link non-Koenig & Bauer equipment to the Koenig & Bauer Cloud, consolidating all production data into the Kyana Data analysis tool. This allows the company to view, analyse, and benchmark performance across its entire machine park via the myKyana portal.

Nathan Elzer (left) and Bernie Elzer III of Grafika Print with a Koenig & Bauer Rapida 106

“Our mission is to lead the print and packaging industry into the future,” said Sandra Wagner, CEO of Koenig & Bauer Kyana. “The successful connection of the third-party machine at Grafika shows that we are not limiting ourselves to our own machines, but are acting as a true partner. We are creating holistic data transparency across the entire machine park so that our customers can make sound, data-driven decisions.”

According to Dr Felix Oberdorf, head of digital development at Koenig & Bauer Kyana, the ability to collect and analyse data from mixed production environments is “the decisive lever for optimising production workflows” and demonstrates “the technological maturity of our digital products.”

Grafika CEO Bernie Elzer III described the integration as “a significant milestone” in improving company efficiency. “The ability to centrally analyse all our production data in Kyana Data has already led to concrete measures with which we have been able to significantly boost our performance,” he said.

Koenig & Bauer Kyana’s digital suite also includes the AI assistant Kyana Assist and the energy management system VisuEnergy X, supporting data-driven production across the full print lifecycle.