Bobst has introduced new technologies and service initiatives at Labelexpo Europe 2025, including the debut of the FlexJet module, a digital-only solution for multilayer label production. The new module aims to help converters expand into higher-margin applications and adapt more easily to changing market demands.

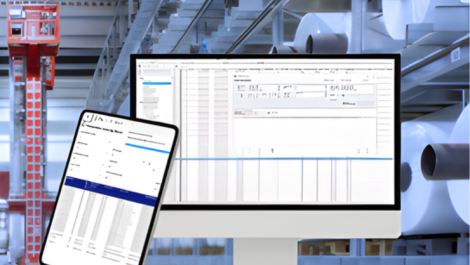

Developed for Bobst’s Digital Master 340 and 510 platforms, the FlexJet module enables fully digital, inline production of complex multilayer labels. The system allows printing on the front, back, adhesive, and liner surfaces in a single pass. This all-digital approach eliminates multiple production steps typically required in traditional or hybrid workflows, reducing setup time, waste, and operational complexity.

“We’re seeing significant growth in the demand for multilayer applications driven by a large number of factors – sustainability and regulatory requirements including product information, nutritional values, and warnings in multiple languages, or for adding promotional content and interactive features,” said Patrick Graber, marketing director of PL Labels. “Bobst already provides solutions for producing multilayer labels using inline flexo and all-in-one machines, and now we add a fully digital option with FlexJet.”

The FlexJet module is currently configured with a single black printbar and uses Bobst inkjet technology with a native resolution of 1200 x 1200dpi. Thanks to Fujifilm Dimatix Samba printheads, this resolution is maintained at full production speeds. The module is intended to support a range of use cases, including short runs, versioning, and variable data printing, helping converters respond quickly to brand owner requirements while maintaining efficiency.

“At Labelexpo, we are demonstrating how our solutions can open doors for converters, allowing them to address a multitude of applications efficiently and profitably,” said Mr Graber. “Whether you’re in labels, flexible packaging or folding cartons, we have the technology and service solutions to meet brand owner demands and requirements.”

In addition to the FlexJet module, Bobst has extended its Application Management service to the label sector. Previously available for folding cartons, corrugated, and flexible packaging, the service provides technical and strategic guidance for converters seeking to improve efficiency, transition to more sustainable materials, or explore new markets. “In an industry where speed, quality, and sustainability drive competitiveness, Application Management offers expert insight into everything from material selection to production optimization and supply chain integration,” said Mr Graber. “The service enables our customers to navigate complex decisions with confidence.”

Bobst also announced a partnership with Belgian consultancy firm Co-ëfficiënt, aimed at helping customers improve production processes and increase profitability. The collaboration focuses on optimising overall equipment effectiveness, reducing setup time, improving colour control, and supporting sustainable practices across print operations. “We are very pleased to accelerate our service offering with this strategic new partnership,” said Mr Graber. “By combining Co-ëfficiënt’s consultancy experience with Bobst’s technology expertise, customers will be able to unlock the full potential of their equipment, optimise production based on data, and ensure consistent quality across technologies.”