Gallus, a subsidiary of Heidelberg, has launched two new label printing presses at Labelexpo Europe 2025: the Gallus Alpha, a digital-only press, and the Gallus Five, a hybrid model. The new machines expand the company’s “System to Compose” portfolio, developed in collaboration with Heidelberg to address growing demand for faster, more flexible, and high-quality label production.

Label production is expected to grow at a compound annual growth rate of 4.0% through 2030, driven by sectors such as retail, logistics, pharmaceuticals, and personal care, stated Gallus. As digital printing gains a larger share of the market, these developments aim to help converters meet evolving production needs.

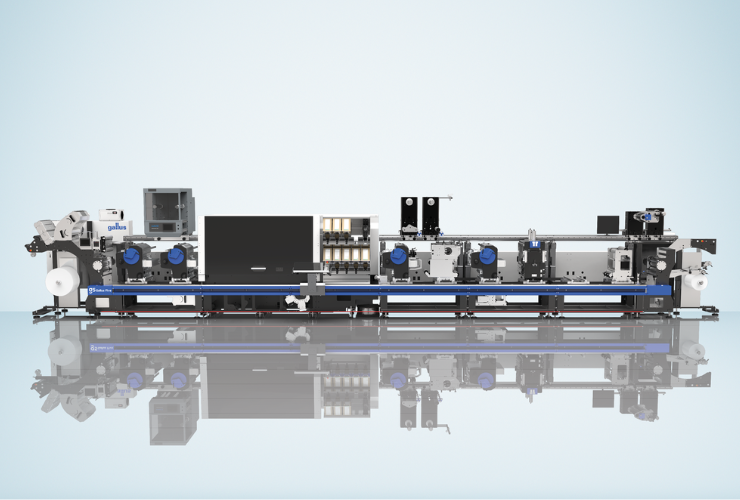

Gallus Five

The Gallus Five is built on the existing Gallus Labelmaster platform and integrates digital and conventional technologies into a single high-performance system. It offers production speeds of up to 100m/min at a resolution of 1200 x 1200dpi. The press is available in 340mm and 430mm widths and includes modular configurability and in-line finishing. Key features include reduced ink consumption, automated job changes, and industrial-level throughput. The machine also uses the new Heidelberg Saphira UV05 ink set, designed to lower total cost of ownership while covering up to 95% of the Pantone colour gamut and meeting updated safety standards. A new semi-rotary die cutter, the SDC Pro, complements the system with high-speed cutting, fast changeovers, and optional cutting-depth adjustment.

The Gallus Alpha, meanwhile, is designed as an entry-level digital press for converters seeking a more accessible and cost-effective route into digital label production. It operates at 65m/min with the same high-resolution print quality of 1200 x 1200dpi. Offered in two configurations – four-colour plus white and six-colour plus white – the Alpha features a roll-to-roll design and integrates easily into existing workflows. It is aimed at markets where shorter runs and faster turnarounds are essential.

To support customers adopting these technologies, Gallus also announced the launch of the Gallus Print Academy. The training initiative offers on-site education to help printers transition to hybrid and inkjet systems or deepen their expertise with existing equipment. The Academy reflects the company’s wider goal of supporting long-term industry development through practical knowledge and hands-on support.

David Schmedding, chief technology and sales officer at Heidelberg, said the new releases align with the company’s growth strategy. “Together, we’re investing in technologies that deliver end-to-end solutions for efficient, highly productive and cost-effective label production,” he said. “These developments reaffirm our role as a systems integrator in this key market segment.”